E-mail:admin@cerampart.com

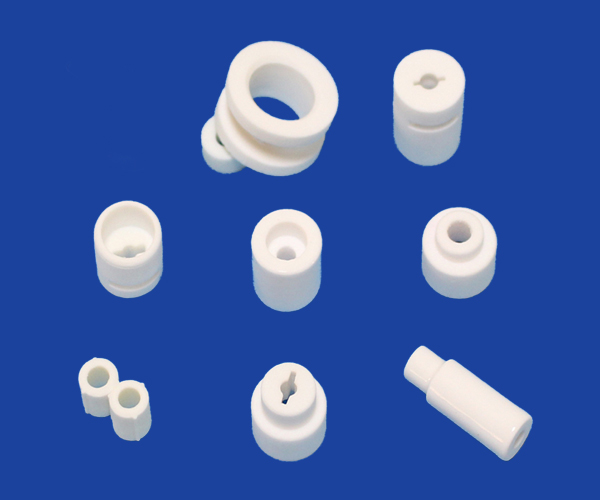

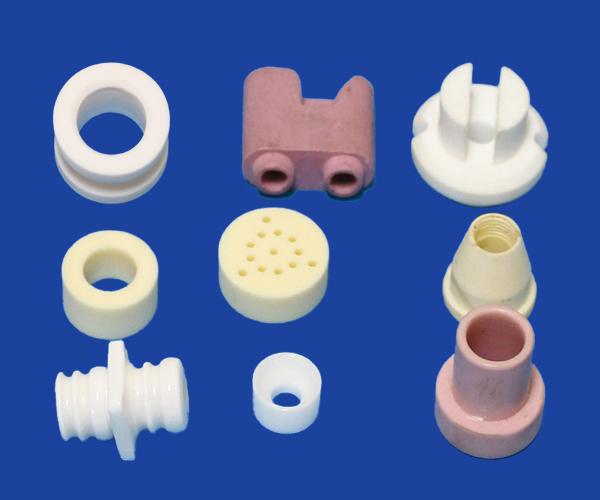

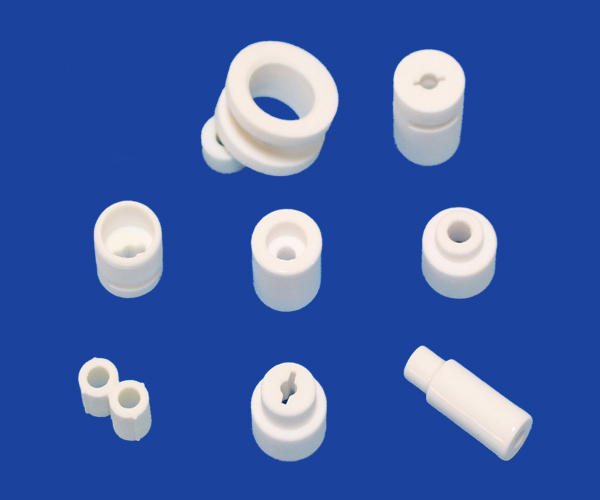

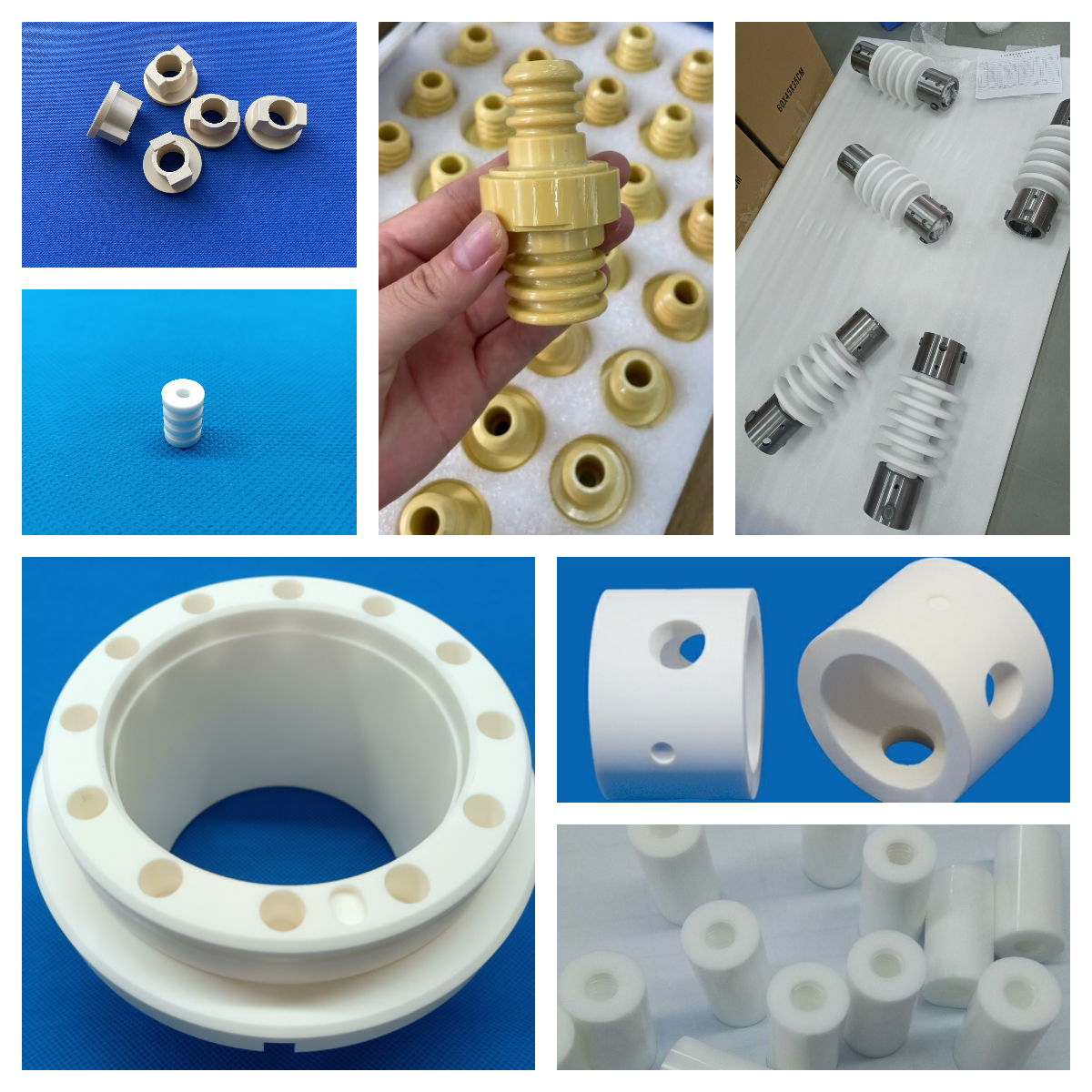

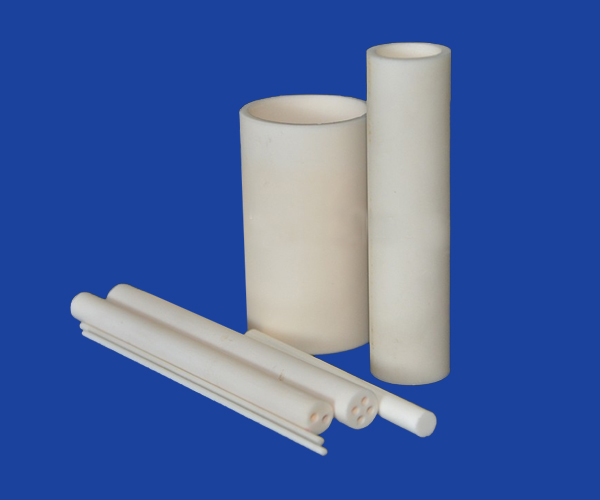

Alumina ceramic insulator Insulation tube High temperature Ceramic tube insulators beads

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Mini-OD: 0.02mm;Max-length: 500mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Alumina ceramic insulator Insulation tube High temperature Ceramic tube insulator beads

The ceramic tube insulators are available in stock. The tube insulators are constructed of zirconia ceramics , alumina ceramic and other advance ceramics that has superior gas and vacuum tightness and excellent insulating properties even at elevated temperatures.

Ceramic dome head interlocking insulating beads for flexible electrical insulation on wires

Steatite material has excellent electrical resistance at high temperatures, good mechanical strength and a very low dielectric loss factor.

Bead size outside diameter 5.0mm, inside diameter 2.0mm, overall height 6.0mm, height to shoulder 4.8

Notes:

Wire-to-ceramic coaxial clearance does affect overall flexibility; therefore, as wire size increases, flexibility decreases.

The electrical and thermal ratings specified are of safe operating limits determined by various factors including material properties, mechanical design, and the intended operating environment. All electrical ratings are based on operation with one side in dry atmosphere and the other side in vacuum of less than 1 x 10-4 Torr. All VacuCAD files as well as any dimensions shown or listed in our ordering tables do not include manufacturing tolerances and are provided for reference only.

Unless otherwise noted they can also be supplied in longer lengths . We can also custom cut shorter lengths to your specifications. Contact us with your specific requirements.

Other sizes available on request

We produce and sale ceramic inslating bead with multi sizes for industry applications. and also offer custom service for our customers. for more details like diameter, instocks, price, delivery time, price etc, please contact us soon, our ceramic engineer feedback within i hours. thanks

Our official E-mails: admin@cerampart.com (Mr admin)

|

Ceramic tube insulators have a best performance for industry. which made of the advance ceramic raws: 95%-99.99% alumina ceramic(Al2o3); zirconia ceramics; silicon carbide ceramics; silicon nitride ceramics..etc 1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)... 2. Hardness Strength, Wear Resistance Up To Mohz 9.0 ; HRA 80-90... 3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm... 4. High Polished Surface Up To Rz0.8(Ra0.1) ... 5. Superior Mechanical Strength, MAX 10 MPa.m1/2 Fracture toughness, 6. Pressure Resistance, Max 2300MPa compressive strength... 7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance... 8. Long Service Life... 9. Other excellent property The hole of ceramic tubes: Single bore, double bore, four bore, dee tubing, oval shapes, custom shapes... |

|

Our Customers

OEM ceramic spare components and enjoys on-going relationships with businesses of all sizes in dozens of industries, in addition to the markets showcased at the top of this page, including:

§ Cable & Fiber Optics

§ Electric & Gas Welding Equipment

§ Electrical Apparatus & Wiring

§ Investment Casting

§ Infrared Equipment

§ Microwave Equipment

§ Refractory Furnaces

§ Thermocouples

§ Semiconductors

§ Soldering Equipment

§ Spare components for equipment parts

The some types of the ceramic tube insulators like below:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic tubes, rod or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL