E-mail:admin@cerampart.com

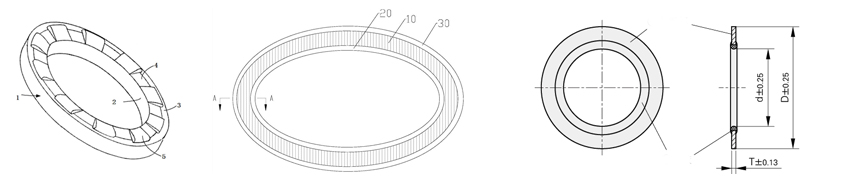

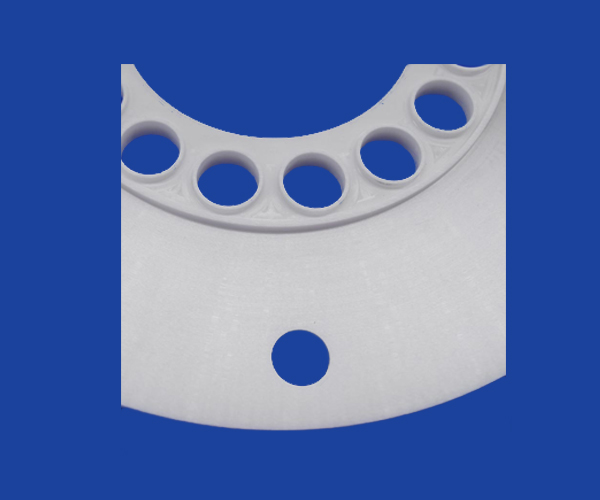

Ceramic Seal Rings High hardness and Mechanical Alumina Zirconia Seal Wafer Ring

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

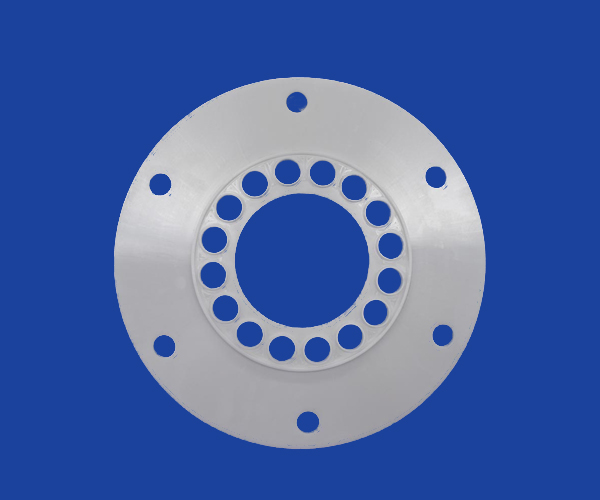

Ceramic Seal Rings High hardness and Heat Resistance Alumina Zirconia Seal Wafer Ring

Ceramic sealing ring as a kind of sealing parts have high performance than other metal rings in special environments. The ceramic sealing rings can be use for high temperature, insulating etc.

Ceramic seal rings are manufactured by our ceramic sealing engineer with advanced technology using high purity ceramics like: alumina ceramic ,zirconia ceramic ,silicon ceramic etc.

Our ceramic sealing ring are available in various dimensions, these ceramic rings can also be customized as per the requirements of customer. Recognized for high resilience, abrasion resistance, good impact resistance and high durability, mechanical etc.

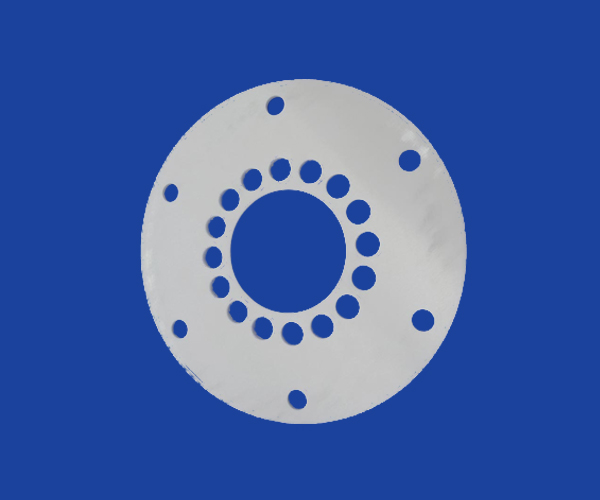

The types of ceramic sealing ring we can produces:

Ceramic sealing O ring

Ceramic sealing washer ring

Ceramic sealing gasket ring

Ceramic sealing tube ring

Ceramic sealing bushing ring

Ceramic sealing spacer ring

others

Company Advantage

OEM factory, High quality, Precision processing, Pipelining assembly, 100% QC process, Plentiful stocks, Fast and Safe shipping.

Part of us oem ceramic seal rings specifications

| T | D | d | Techi | ||||

| Allowable pressure | Tightening torque | Hole diameter | Sink hole diameter | ||||

| N・m | |||||||

| min. | max. | max. | min. | ||||

| 0.7 | 6 | 2.9 | 10MPa | 0.7 | 1.4 | 3.3 | 6.6 |

| 7.5 | 3.9 | 10MPa | 1.1 | 3.1 | 4.2 | 8.2 | |

| 9 | 4.9 | 10MPa | 2.2 | 6.5 | 5.2 | 10 | |

| 1 | 10.5 | 5.9 | 10MPa | 3 | 15 | 6.2 | 11.5 |

| 13.5 | 7.9 | 10MPa | 4.5 | 37 | 8.2 | 14.5 | |

| 1.5 | 17 | 9.9 | 10MPa | 6 | 73 | 10.4 | 18 |

| 19 | 11.9 | 10MPa | 8 | 115 | 12.5 | 21 | |

| 25 | 15.9 | 10MPa | 10 | 290 | 16.5 | 27 | |

Us can be custom multi type ceramic sealing ring according to customer requirements

Feature of ceramic sealing ring

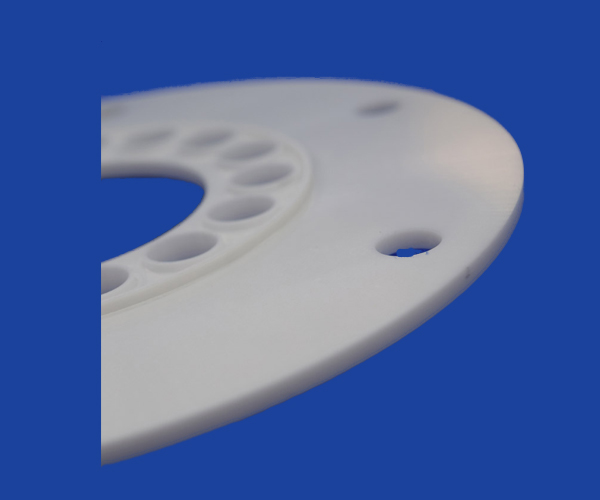

1) High hardness.

2) High heat resistance : Alumina ceramic has excellent thermal stability,which means that it is

widely used in areas where resistance to high temperatures is essential.

3) Good wear resistance : Alumina ceramic is the material of choice for alumina wear parts.

4) High electrical resistivity : Alumina is an electrically insulating material.

5)High corrosion resistance : It is insoluble in water and only slightly soluble in strong acid and

alkaline solutions.

6) Good chemical stability of alumina leads to high corrosion resistance.

The properties of ceramic sealing ring

| · Flexural strength | · Chemical resistance | · Electrical insulation | · Corrosion resistance | · Dielectric strength |

| · Wear resistance | · Temperature resistance | · Thermal conductivity | · High voltage | · Hardness... |

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

....

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Customization & Machining Service

As a professional manufacturer of ceramic sealing ring.We can custom the sepcial specifications of ceramic sealing ring or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramic sealing rings,please contact our engineers in time >>> |

|

Ceramic sealing ring adopts advanced hot vulcanization technology to make special alumina corundum wear-resisting ceramics according to certain layout.This structure not only gives play to alumina ceramics resistance to high temperature wear and corrosion resistance, but also gives play to the characteristics of high strength, high toughness and good sealing of rubber materials, integrated design, easy to replace and install.

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL