Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com

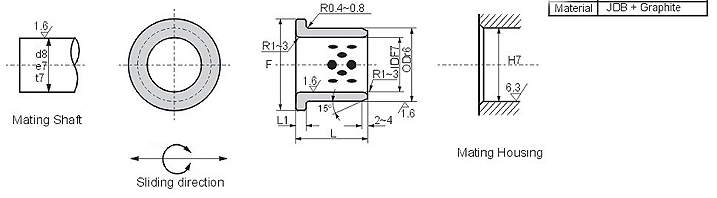

| d | D | IDF7 | ODm6 | F | L1 | L-0.10 | |||||||||||

| -0.1 | -0.3 | ||||||||||||||||

| 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 80 | 100 | ||||||||

| 10 | 14 | 10 | 0.04 | 14 | 0.034 | 22 | 2 | 1015 | 1020 | ||||||||

| 0.025 | 0.023 | ||||||||||||||||

| 12 | 18 | 12 | 0.05 | 18 | 25 | 3 | 1215 | 1220 | |||||||||

| 13 | 19 | 13 | 0.032 | 19 | 0.041 | 26 | 1315 | 1320 | |||||||||

| 14 | 20 | 14 | 20 | 0.028 | 27 | 1415 | 1420 | ||||||||||

| 15 | 21 | 15 | 21 | 28 | 1515 | 1520 | 1525 | 1530 | |||||||||

| 16 | 22 | 16 | 22 | 29 | 1615 | 1620 | 1625 | 1630 | |||||||||

| 20 | 30 | 20 | 0.061 | 30 | 40 | 5 | 2015 | 2020 | 2025 | 2030 | 2040 | ||||||

| 25 | 35 | 25 | 0.04 | 35 | 0.05 | 45 | 2515 | 2520 | 2525 | 2530 | 2540 | ||||||

| 30 | 40 | 30 | 40 | 0.034 | 50 | 3020 | 3025 | 3030 | 3035 | 3040 | 3050 | ||||||

| 31.5 | 40 | 31.5 | 0.075 | 40 | 3120 | 3135 | |||||||||||

| 35 | 45 | 35 | 0.05 | 45 | 60 | 3520 | 3530 | 3540 | 3550 | ||||||||

| 40 | 50 | 40 | 50 | 65 | 4020 | 4030 | 4040 | 4050 | |||||||||

| 45 | 55 | 45 | 55 | 0.06 | 70 | 4530 | 4540 | 4550 | 4560 | ||||||||

| 50 | 60 | 50 | 60 | 0.041 | 75 | 5030 | 5040 | 5050 | 5060 | ||||||||

| 55 | 65 | 55 | 0.09 | 65 | 80 | 5540 | 5560 | ||||||||||

| 60 | 75 | 60 | 0.06 | 75 | 0.062 | 90 | 7.5 | 6040 | 6050 | 6080 | |||||||

| 63 | 75 | 63 | 75 | 0.043 | 85 | 6367 | |||||||||||

| 70 | 85 | 70 | 85 | 0.073 | 105 | 7050 | 7080 | ||||||||||

| 75 | 90 | 75 | 90 | 0.051 | 110 | 7560 | |||||||||||

| 80 | 100 | 80 | 100 | 120 | 10 | 8060 | 8080 | 80100 | |||||||||

| 90 | 110 | 90 | 0.107 | 110 | 0.076 | 130 | 9060 | 9080 | |||||||||

| 100 | 120 | 100 | 0.072 | 120 | 0.054 | 150 | 10080 | 100100 | |||||||||

| 120 | 140 | 120 | 140 | 0.088 | 170 | 12080 | 120100 | ||||||||||

| 0.063 | |||||||||||||||||

| · Flexural strength | · Chemical resistance | · Electrical insulation | · Corrosion resistance | · Dielectric strength |

| · Wear resistance | · Temperature resistance | · Thermal conductivity | · High voltage | · Hardness... |

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve