E-mail:admin@cerampart.com

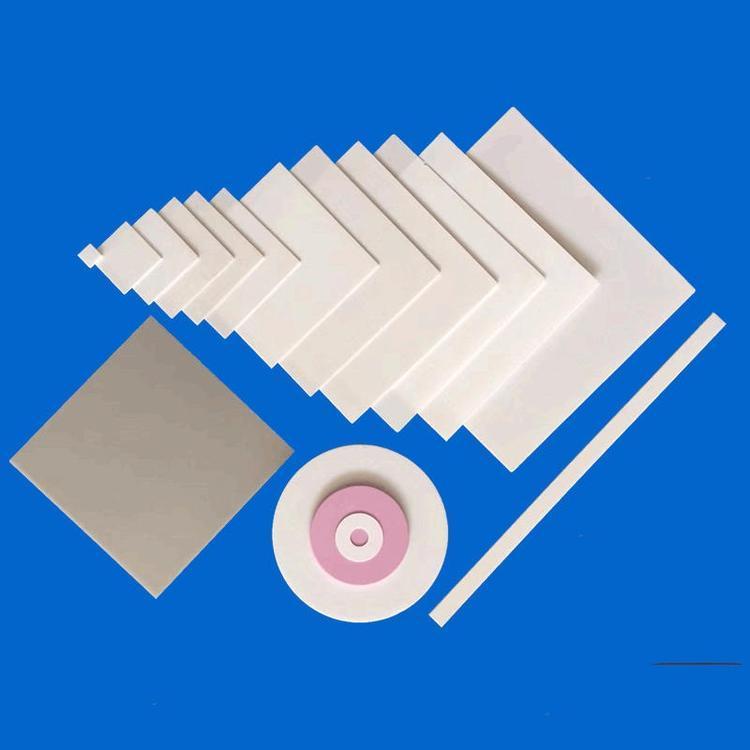

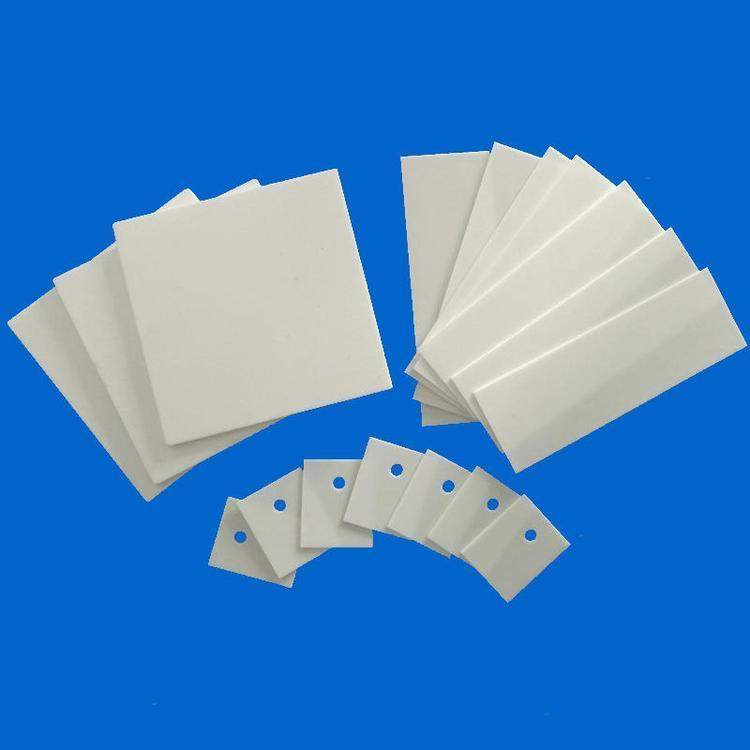

Ceramic piece plate wear and pressure-resistant ceramic sheet

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Max Length/width:450mmThickness:0.2mm...

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Ceramic piece plate wear and pressure-resistant ceramic sheet

The main forming method we use is tape-casting, we are dealing with a variety of selection of thickness from 0.25mm to 20mm. Besides, we support prototyping case to mass production.

Specification of Ceramic piece plate wear and pressure-resistant ceramic sheet

● Material : 96% alumina, 99% alumina, 99.5% alumina, zirconia optional

● Dimensions: Side length max. 300mm x 400mm, Thickness can be 0.2mm to 20mm

● Surface treatment: Fine ground, Well-polished, Metallization, Glazed

● The checklist of standard size with the stock level in 96% alumina:

|

Size (Unit: mm) |

Thickness(Unit: mm) | |||

| 132 x 142 | 1.0 | 0.635 | 0.80 | |

| 114 x 114 | 1.0 | 0.635 | 0.80 | 0.385 |

| 109 x 130 | 1.0 | 0.635 | 0.80 | |

| 109 x 109 | 1.0 | 0.635 | 0.80 | |

| 280 x 87 | 0.635 | |||

| 395 x 83 | 1.0 | |||

| 122 x 120 | 1.0 | 0.80 | ||

| 109 x 120 | 1.0 | 0.635 | 0.80 | |

| 138 x 190 | 1.0 | 0.635 | 0.76 | |

| 127 x 127 | 1.0 | 0.635 | ||

| 280 x 240 | 1.0 | 0.635 | ||

The advantages of Ceramic piece plate wear and pressure-resistant ceramic sheet:

1. High thermal conductivity, up to 24 W/m.k at 25℃

2. Good thermal shock resistance, greater than 220 T(℃)

3. Good surface roughness, flatness to be 0.05mm

4. High dielectric strength, low dielectric constant and dielectric loss.

5. Laser cutting or precision machining cutting makes tight tolerance.

Typical applications of Ceramic piece plate wear and pressure-resistant ceramic sheet:

LED packages, Power modules, Substrates for chip resistors, HIC substrates for heat dissipation, FAX substrates for thermal printer head, Substrates for automotive parts, Substrates for general thick film application, Substrates for sensor parts, Substrates for electronic devices

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL