E-mail:admin@cerampart.com

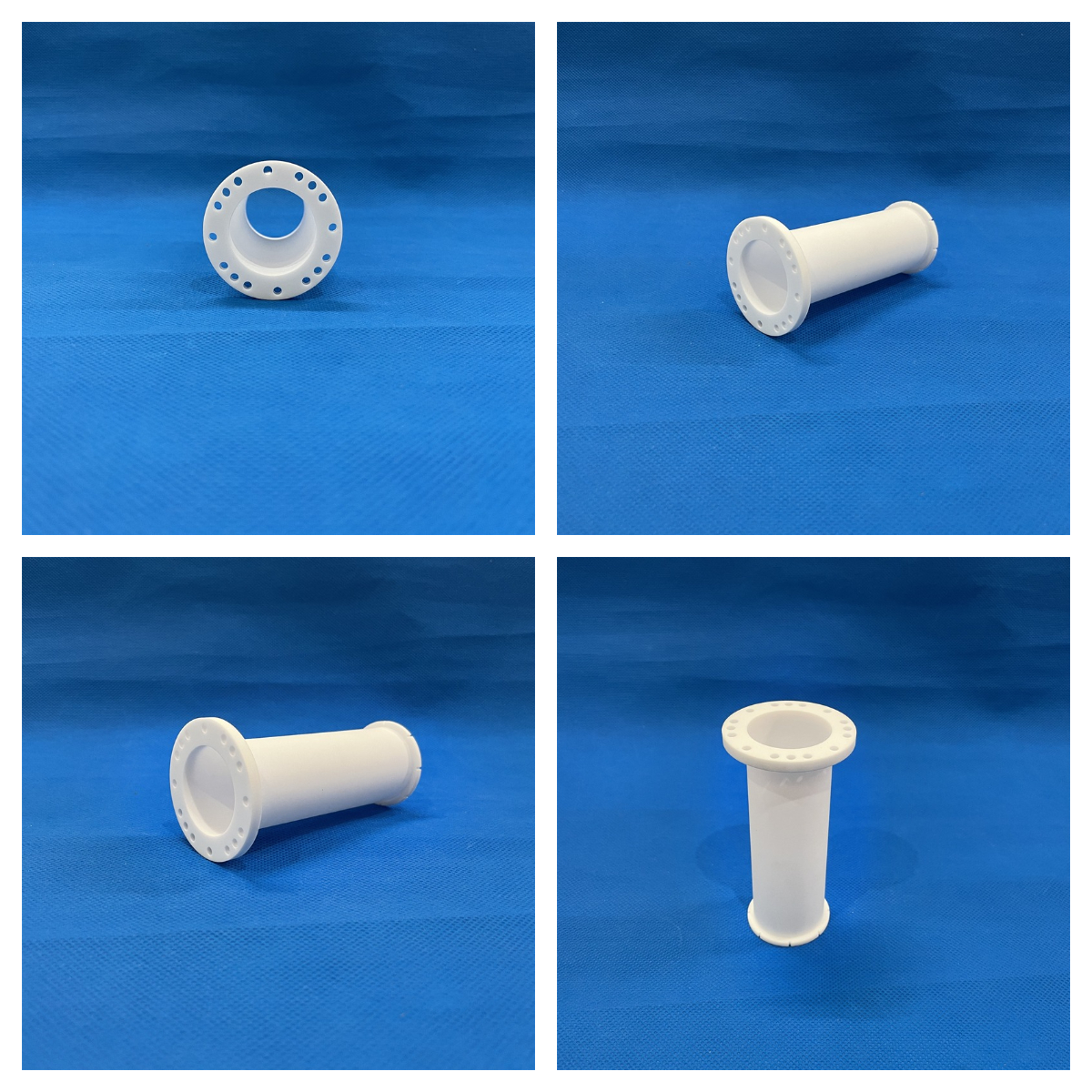

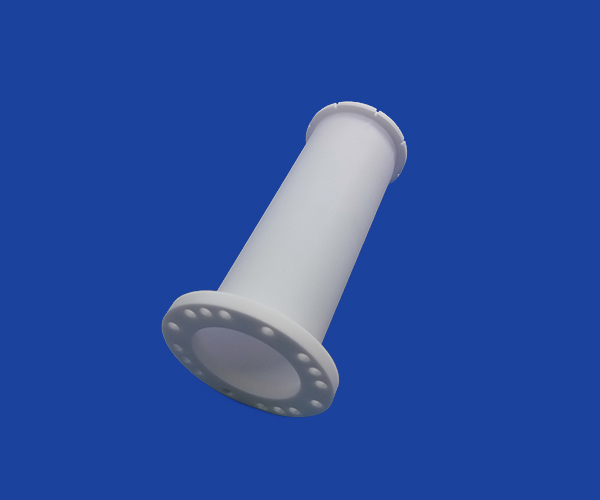

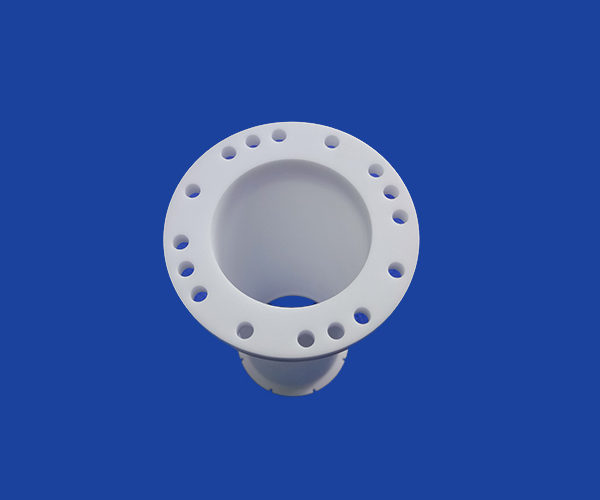

Ceramic Pipe Fitting High temperature resistant Insulated Alumina Ceramic Tube with Flange Ceramic Liner Pipe

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Ceramic Pipe Fitting High temperature resistant Insulated Alumina Ceramic Tube with Flange Ceramic Liner Pipe

Alumina ceramic flange pipes

ceramic pipe fitting most cost effective wear resistant for elbow and tee

ceramic pipe fitting use paste, welding or dovetail to fix wear-resistant ceramic on the inner wall of the pipe, forming a strong anti abrasion layer. With superior wear resistance it has been widely used in industrial enterprises pneumatic conveying, hydraulic transmission system, especially the erosion site of the elbow, tee, and distributor. It is one of the best channels with its cost effective.

Suitable medium

Solid particles such as coal powder, ash, slag and slurry, such as coal slurry, slag, and liquid aluminum.

Application

Widely used in metallurgy, mining, electricity, coal, petrochemical and other industries, gas solid, liquid solid conveyor system, especially for serious damage occurs on the elbow, three links.

Product Features:

Excellent wear resistance

Adopting alumina ceramics as liner, the lifetime of the pipe is above 10 times than normal hardened steel.

Corrosion resistance

Alumina ceramic has advantages of seawater erosion, acid and alkali resistance, also scaling protection.

Friction promotion

Inner surface smooth and without erosion, the inner smoothness of pipes is superior to any other metal pipes.

Using temperature

The SHP-P compound pipe can be long time running under a temperature range of -50--800℃.

Light weight

The weight of SHP-P compound pipe is just arriving at half of casting stone pipe and approximately 50% of alloy pipe. With advantages of wear and corrosion resistance, the lifetime of SHP pipe is outstandingly longer than other wear resistant pipes hereby the cost of assembly and running is largely reduced.

Easily assembly

Due to its light weight and good weld ability, it can be assembled easily with welding or flange connection and remarkably reduce the fixing cost.

Custom OEM will be shipped within 15 days after determining the parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the ceramic plates, please contact us or email:admin@cerampart.com

Machining process

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

Mingrui ceramic parts property

| · Flexural strength | · Chemical resistance | · Electrical insulation | · Corrosion resistance | · Dielectric strength |

| · Wear resistance | · Temperature resistance | · Thermal conductivity | · High voltage | · Hardness... |

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL