E-mail:admin@cerampart.com

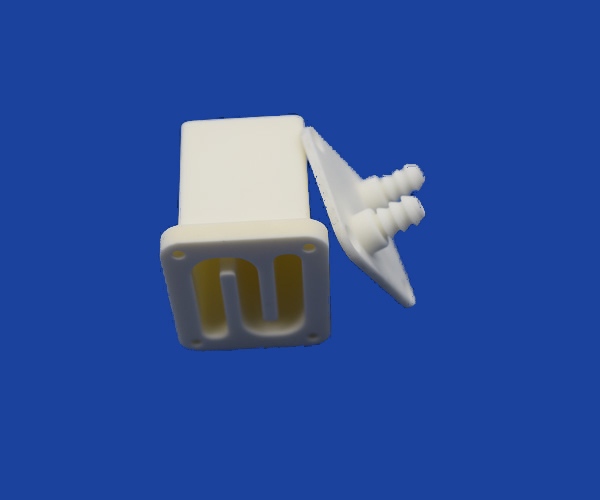

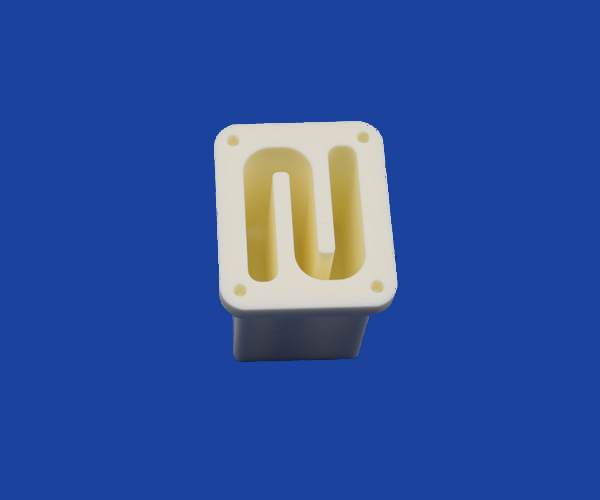

Ceramic fittings for tank

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Ceramic fittings for tank

Water tank ceramic accessories with high performance, such as wear resistance, high temperature resistance, corrosion resistance, smooth surface;

Ceramic fittings are suitable for water tank use.

Can be very good to improve the use of various types of water tanks.

Y-TZP (Yttria Stabilized Zirconium Oxide) is a specialty material for critical structural ceramic applications. The material is almost completely tetragonal in structure and is partially stabilized using about 3 mol% of Yttria (Y2O3).

Key Properties

• Low thermal conductivity

This material has the highest flexural strength of the zirconia materials particularly when processed using a HIP (Hot Isostat Press). The excellent mechanical properties of this material are a result of a very small grain size, extremely low porosity, and a good deal of transformation toughening.

The Y-TZP material's extremely fine grain size makes it ideal for creating sharp blades that will, because of its excellent wear resistance, remain razor sharp. It is used in tooling and process applications for its strength, superior toughness, and excellent abrasion resistant.

Mg-PSZ(Magnesium oxide)is used as the stabiliser. This cubic phase material is loaded with tiny tetragonal phase precipitates, giving a very high level of transformation toughness. Mg-PSZ is able to give the highest level of fracture toughness.

It has excellent mechanical properties, including high strength, fracture toughness, wear resistance, good thermal shock and low thermal conductivity.

Due to these characteristics it finds use in high wear and corrosion applications including valves, pumps and liners. It is the material of choice for the chemical processing and petrochemical industries

The Y-TZP material's extremely fine grain size makes it ideal for creating sharp blades that will, because of its excellent wear resistance, remain razor sharp. It is used in tooling and process applications for its strength, superior toughness, and excellent abrasion resistant.

Mg-PSZ(Magnesium oxide)is used as the stabiliser. This cubic phase material is loaded with tiny tetragonal phase precipitates, giving a very high level of transformation toughness. Mg-PSZ is able to give the highest level of fracture toughness.

It has excellent mechanical properties, including high strength, fracture toughness, wear resistance, good thermal shock and low thermal conductivity.

Due to these characteristics it finds use in high wear and corrosion applications including valves, pumps and liners. It is the material of choice for the chemical processing and petrochemical industries

Key Properties

• Low thermal conductivity

• High density

• Chemical inertness

• Resistance to molten metals

• Wear resistance

• High fracture toughness

Typical Uses

• Precision ball valve balls and seats

• Deep well down-hole valves and seats

• Rollers and guides for metal tube forming

• Hot metal extrusion dies

• Marine pump seals and shaft guides

• Oxygen sensors

• Fuel cell membranes Ballistic armor

• Chemical inertness

• Resistance to molten metals

• Wear resistance

• High fracture toughness

Typical Uses

• Precision ball valve balls and seats

• Deep well down-hole valves and seats

• Rollers and guides for metal tube forming

• Hot metal extrusion dies

• Marine pump seals and shaft guides

• Oxygen sensors

• Fuel cell membranes Ballistic armor

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL