E-mail:admin@cerampart.com

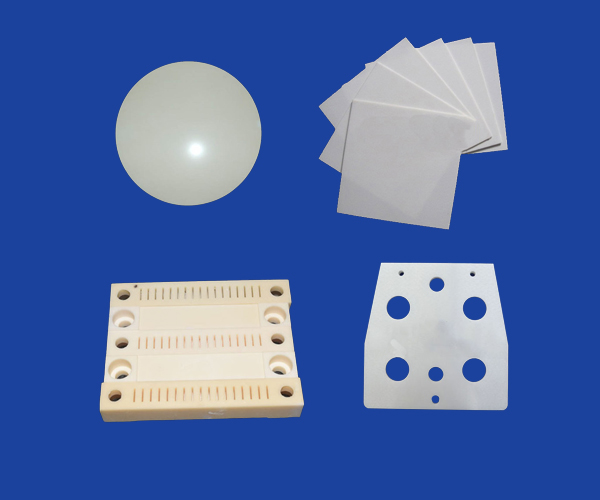

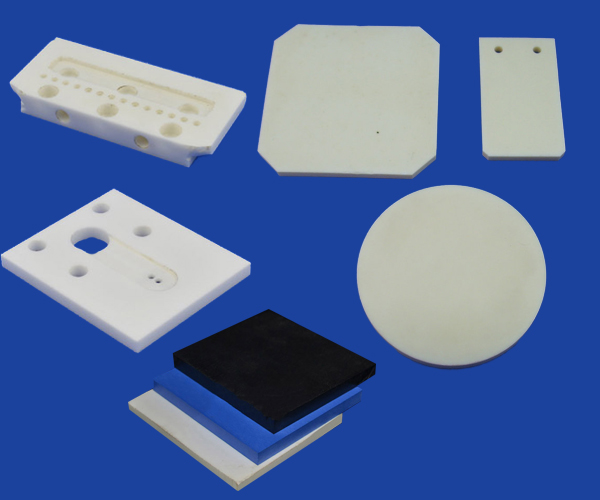

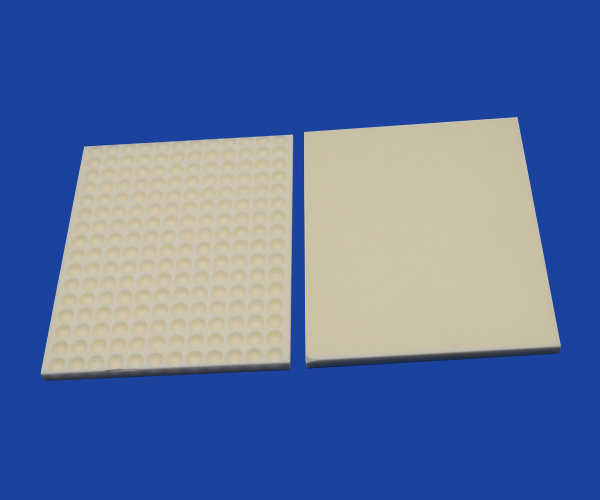

Machined ceramic panels alumina plate panel zirconia ceramics

- Materials:95%--99.99%Alumina (Al2O3)/ Zirconia(ZrO2:TTZ,YTZP, ZDY)

- Sizes:custom

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Machined ceramic panels alumina plate panel zirconia ceramics

Ceramic panels can be used for many industies due to machinable ceramic panels have a excellent ceramic property.

Us machined ceramic panels included alumina panels which called Al2O3 alumina ceramic panels, zirconia ceramic panels and other ceramic raw panels.

The ceramic panel process of high pressure, heat is virtually impossible. Although standard ceramic panels are available, The ceramic can be laid out with staggered or aligned joints. Both tiles and cylinders can be used of different sizes and shapes.

Our alumina ceramic panels:

1. Types of alumina panels: our alumina ceramic panel plate made by 95% to 99.99% purity Al2O3 alumina raws.

95%--99.99% Alumina (Al2O3) panel

High purity alumina ceramics panel:

99.99% Alumina ceramic panel ; 99.9% Alumina ceramic panel,

Ordinary alumina ceramics panel:

99.7% Alumina ceramic panel,99.5% Alumina ceramic panel ,99% Alumina ceramic panel,97% Alumina ceramic panel, 96% Alumina ceramic panel ,95% Alumina ceramic panel

Which Alumina ceramic panel is most suitable depends on the customer's requirement.

Our zirconia ceramic panels:

Mg-PSZ (Magnesia - Partially stabilised zirconia panel) – Highest toughness grades

Zirconia panel MS – “Maximum Strength” grade ideal for wear and corrosion solutions and used extensively in materials handling industries.

Zirconia panelTS – “Thermal Shock” grade provides high resistance to thermal shock and is used in non-ferrous metal extrusion applications.

Y-TZP (Yttria - Tetragonal zirconia polycrystal) - Highest strength and hardness grades with a finer grain structure:

Zirconia 3Y-TZP – A fine grain grade frequently used in the Petrochemical Industry and for applications required to maintain a sharp edge.

Y-FSZ (Yttria - Fully stabilised zirconia) - No transformation toughening.

Zirconia 8Y – An Yttria-Fully stabilised zirconia panel used in applications requiring high temperature oxygen diffusivity/electrical conductivity.

Which zirconia ceramic panel is most suitable depends on the customer's requirement.

Company Advantage

OEM factory, High quality, Precision processing, Pipelining assembly, 100% QC process, Plentiful stocks, Fast and Safe shipping.

Produce and machining

We can produce different sizes and shapes of the machinable ceramic plate for specific applications to different custom products.Such as drilling, polishing, stripes, concave and convex, screw holes, metal parts position and so on

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

Parts of us oem machined ceramic panels

| Length (inch) | Thickness (inch) | Width (inch) |

| 1.95 | 0.0195 | 0.78 |

| 2.73 | 0.156 | 1.365 |

| 2.34 | 0.0975 | 0.624 |

| 4.29 | 0.1365 | 1.755 |

| 4.875 | 0.039 | 1.833 |

Remark: our Machinable ceramic plate can be custom by a drawing,

Size of our machined ceramic panels:

Maximum length as 550mm; Thinnest thickness as 0.02mm; Widest width as 550mm

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL