E-mail:admin@cerampart.com

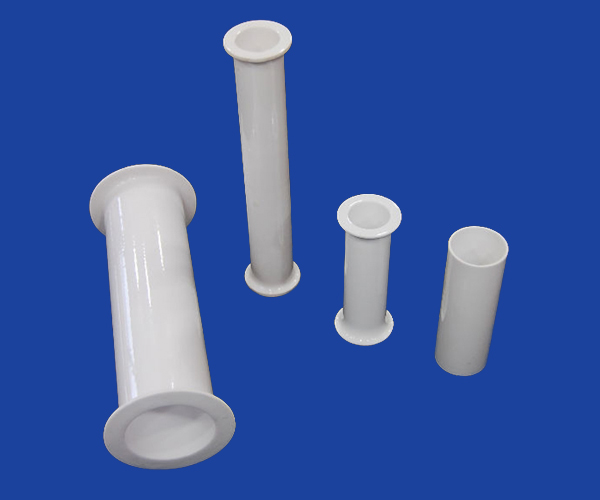

Ceramic tube ferrule inserts

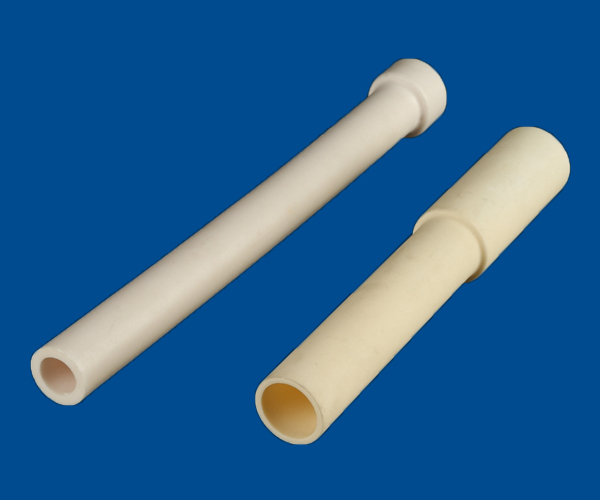

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

ceramic tube ferrule inserts

Ceramic Tube insert also called ceramic ferrule which is inserted into the end of a heat exchanger tube to provide a protective function. The purpose of a ceramic tube insert is to either be sacrificial to the effects of inlet-end erosion, corrosion, impingement to induce a fluid to fall on the ID of a tube in a falling film exchanger; or to transfer extremely high heat past the tube sheet to the exchanger tubes.

Each of the above applications requires a specific style of design. At NSI, we manufacture ceramic tube inserts for all applications, providing the necessary drawings required.

The advantage of the ceramic tube ferrule inserts

1) Protect inlet-end erosion & corrosion

2) Act as a protective layer

3) Reduce the medium impact

4) Transfer extremely high heat past the tube sheet to the exchanger tubes.

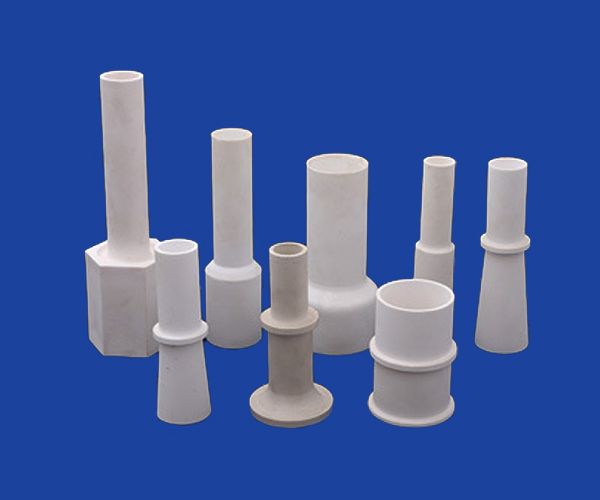

Types of ceramic tube insert/ferrules we can produce

Straight Tube Ferrule Insert

Bar Stock Ferrule Insert

Standard Flare Ferrule Insert

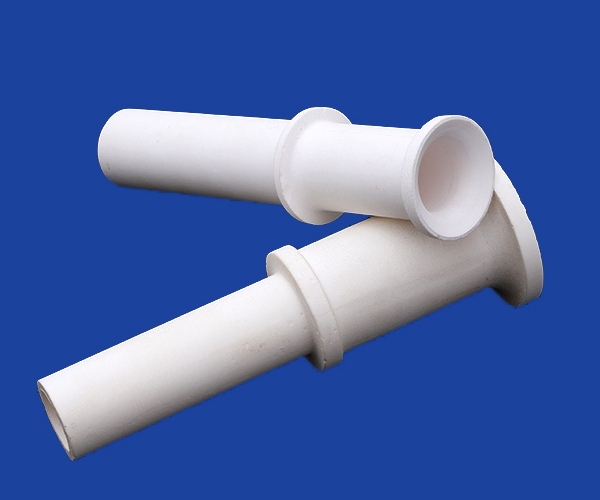

Single Flare with Backcut Tube Insert

Single Flare Long Tube Insert

Double Flare Stepped Tube Insert

Double End Flare Tube Insert

Although inserts are typically only 6″ – 12″ long, some applications have required Shield lengths up to 14 feet!

we are manufactured in various sizes & shapes as per customer requirements.

|

Customization & Machining Service: As a ceramic tube insert manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics tube insert,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL