E-mail:admin@cerampart.com

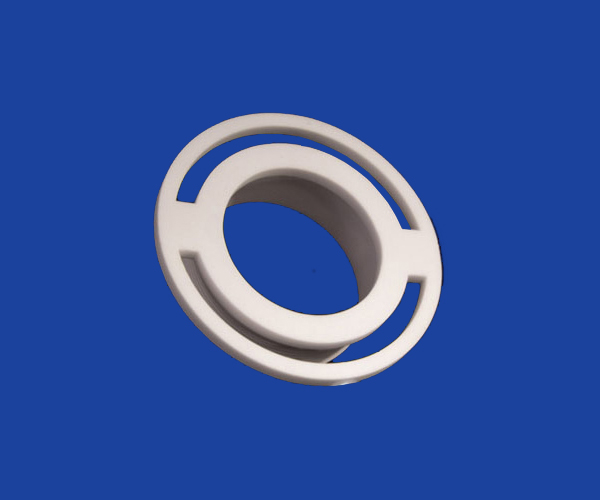

Alumina ceramic ring custom 99.5 to 99.99 purity Al2O3 alumina ceramic rings

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Alumina ceramic ring have a best ability in high temperature resistance, strength, wear, compression , insultation,corrosion etc , due to it made by advance alumina ceramics Al2O3.

High purity alumina ceramics

99.99% Alumina ceramic; 99.9% Alumina ceramic,

Ordinary alumina ceramics

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic

| Properties | Unit | Alumina (AL2O3) | |||

| AL2O3≥95 | AL2O3≥99 | AL2O3≥99.5 | AL2O3≥99.8 | ||

| Volumetric density | g/cm3 | 3.7 | 3.80-3.85 | 3.85 | 3.9 |

| Hardness | HRA≥ | 86 | 88 | 88 | 88 |

| Flexural Strength | Mpa≥ | 300 | 350 | 400 | 400 |

| Maximum temperature | ℃ | 1500 | 1500 | 1500 | 1500 |

| Line expansion coefficient | ×10-6/℃ | 7.5 | 8.2 | 8.2 | 8.2 |

| Dielectric constant | εr(20℃,1MHz) | 9 | 9.2 | 9.2 | 9.2 |

| Media loss | tanδ×10-4,1MHz | 3 | 2 | 2 | 2 |

| Volumetric resistivity | Ω·cm(20℃) | 1013 | 1014 | 1014 | 1014 |

| Breakdown strength | KV/mm,DC≥ | 20 | 20 | 20 | 20 |

| Acidic resistance | mg/cm2≤ | 0.7 | 0.7 | 0.7 | 0.7 |

| Alkaline resistance | mg/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Abrasion resistance | g/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Compressive strength | Mpa≥ | 2500 | 2500 | 2500 | 2800 |

| Flexural Strength | Mpa≥ | 200 | 350 | 350 | 350 |

| Thermalcoefficient | W/m·K(20℃) | 20 | 25 | 25 | 25 |

|

Properties of Alumina/Aluminum Oxide (Al2O3) |

Products and Aplications |

|

Customization & Machining Service: As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL