E-mail:admin@cerampart.com

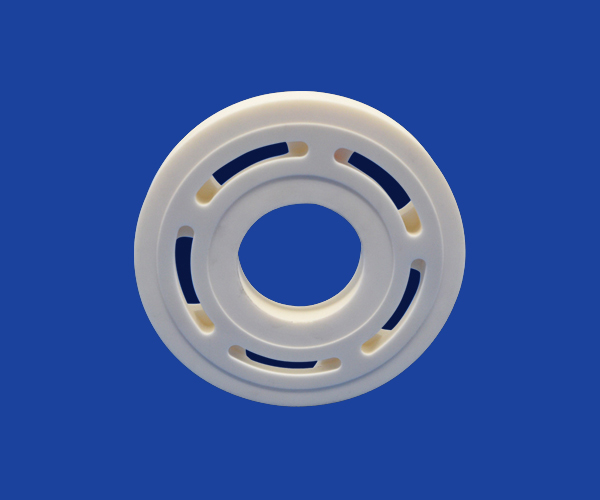

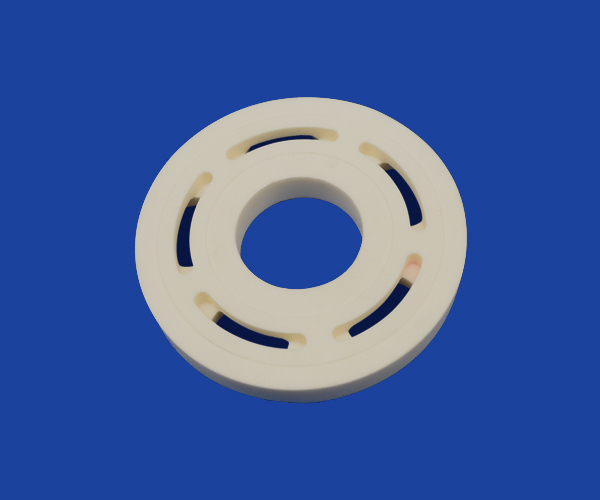

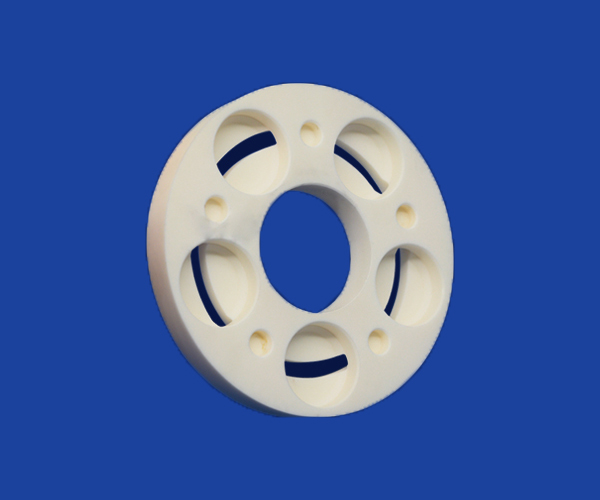

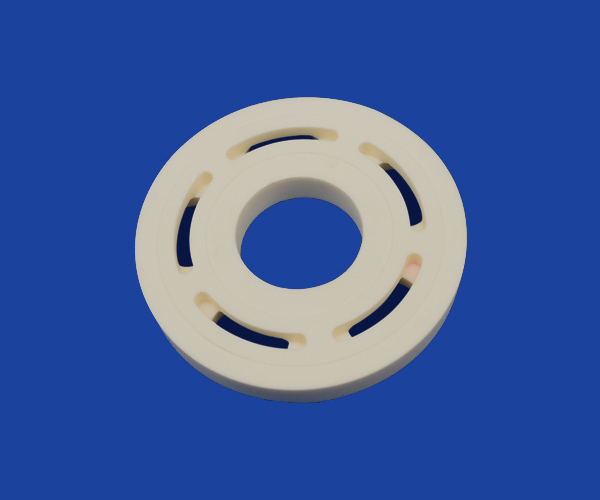

99% alumina ceramic valve plate

- Materials:

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

-

High PrecisionMingrui ceramics adopts advanced equipment and exquisite workmanship, and treats every product to a strict standard.Dimensional accuracy Up to 0.001mm

-

High QualityOur ceramic products have a high temperature resistance, wear and corrosion resistance, hardness, thermal shock, insulating,can be applied to high demand field.

-

ApplicationsMinrui ceramics can be widely used in machinery and electronics, hardware parts, aerospace, chemical, petroleum, automotive, photovoltaic energy。

-

01 one

01 oneHigh machining accuracy

Ceramic products in the processing of different requirements to choose different raw to make products, after repeated testing, calculation, to ensure that each product to meet the standards. -

02 two

02 twoStrict inspection

Mingrui ceramics precision calculation in processing, and the production of products by special people to test, do not let the failed product into the market. -

03 three

03 threeWide range of application

Mingrui ceramics is widely used in mechanical and electronic parts, aerospace, chemical industry, petroleum, automotive military industry, photovoltaic energy and other industrial fields.

Product application area

-

Photovoltaic energy

-

Aeronautics

-

Petroleum chemical industry

-

The car industry

-

Medical apparatus

-

Food filling

Introduction of material

Alumina ceramics

1.Hardness strength

The hardness of rockwell is hra80-90, which is inferior to that of diamond and far superior to that of wear-resisting steel and stainless steel.

2.Best wear resistance

The wear resistance is equal to 266 times of manganese steel and 171.5 times of high chromium cast iron. According to our customer tracking survey for more than ten years, the service life of the equipment can be extended at least 10 times under the same working conditions.

3.Light weight

Its density is 3.5g/cm, only half that of steel, which can greatly reduce equipment load

Zirconia ceramic

1.With excellent wear resistance, chemical corrosion resistance, high temperature resistance and anti - magnetic characteristics, can be used in a particularly harsh environment, and do not pollute the material and the environment

2.With high toughness, high bending strength and high wear resistance, excellent thermal insulation performance, thermal expansion coefficient close to steel and other advantages.

Nanometer alumina

Due to the small particle size, nanometer alumina can be used to make artificial gems, analytical reagents and nanometer catalyst and support, used for luminescent materials can greatly improve its luminous intensity, ceramics, rubber toughening, to several times higher than ordinary alumina, especially to improve the density of ceramics, finish, cold and hot fatigue.Nano-alumina is mainly used in the main parts of YGA laser crystal and the integrated circuit board, and is used in the coating to improve the wear resistance.

Focus on product quality

High quality, High precision

In the spirit of "professional technology, innovation, integrity cooperation, sustainable development" concept, to provide new and old customers with quality products, perfect service

NO.1Ensure the quality

- existing staff a number of professional and technical personnel reached more than 50%

- complete product classification, stable and reliable quality

- products are sold to all provinces and autonomous regions in China, and the domestic sales network is complete

NO.2Standardized operation

- carry out production in strict accordance with the quality specification

- experienced business team, ensure the quality of service

- and can be customized according to customer requirements for the production of ceramic products

NO.3Update advanced equipment

- to provide users with appropriate system solutions, with our superior technology and management to return to the community

- established a sound quality management system and intelligent system integration technical specification, to ensure that the product qualified

NO.4Thoughtful service

- perfect technical support, quick after-sales service, provide maintenance

- provides style customization to ensure accurate size of customer products

- professional logistics distribution, so that customers receive products in time, achieve win-win cooperation

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL