E-mail:admin@cerampart.com

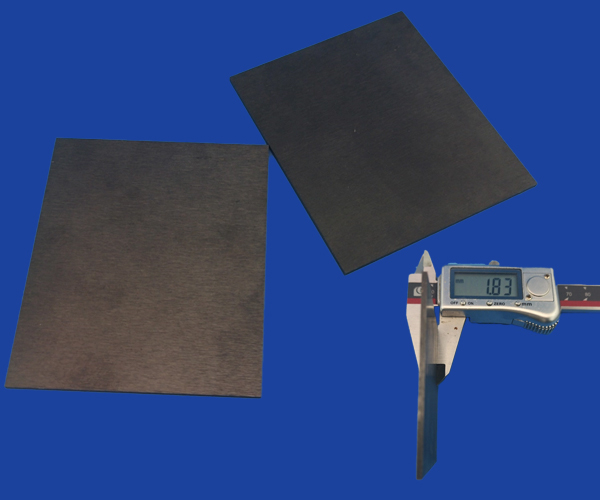

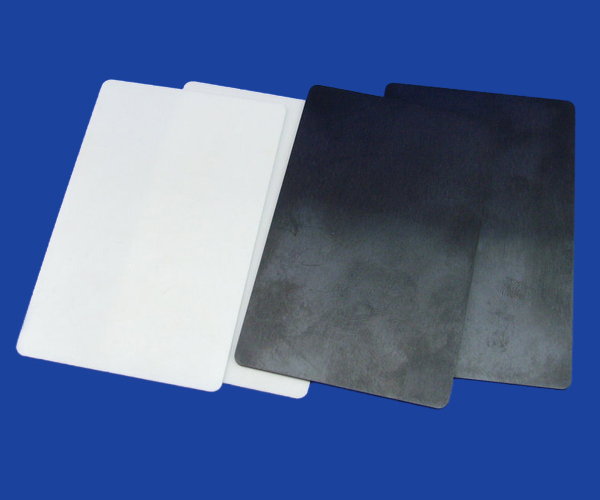

Silicon carbide sheets plate good thermal conductivity high strength and wear resistance ceramic sheet

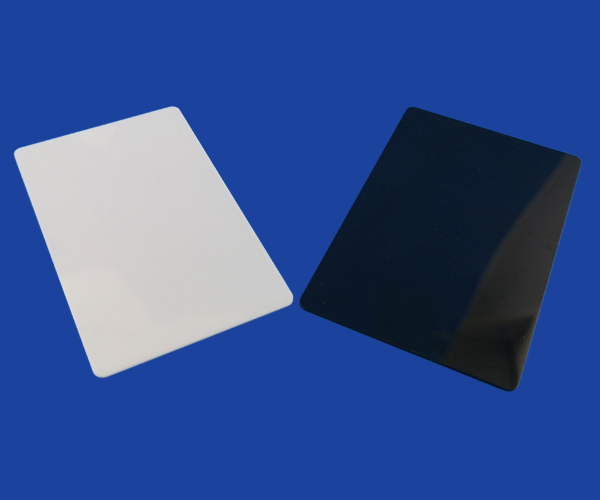

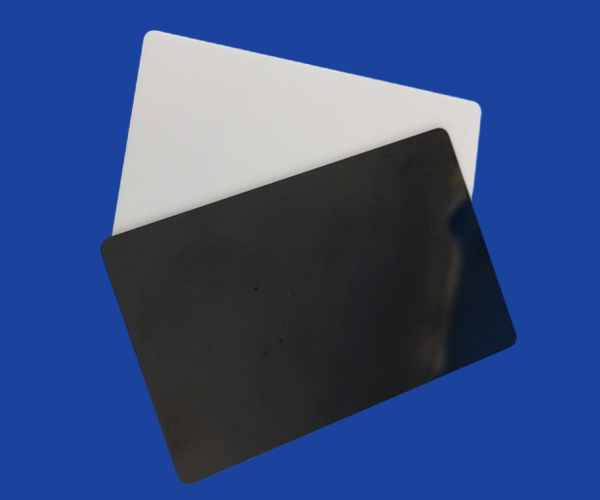

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Max Length/width:450mmThickness:0.2mm...

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Silicon carbide sheets plate good thermal conductivity high strength and wear resistance ceramic sheet

Silicon carbide sheets, Silicon Carbide has properties remarkably similar to those of diamond – it is one of the lightest, hardest, and strongest technical ceramic materials and has exceptional thermal conductivity, resistance to acids, and low thermal expansion.

Silicon carbide sheet material use high purity silicon carbide materials, through evaporation- coagulation under high temperature 2400℃ to get the high purity ceramic with porous network structure, it featured by high strength, high temperature resistance, ground resistance, abrasion and corrosion resistance, oxidation resistance, good thermal shock resistance, high thermal conductivity, good heat transfer effect.

Recrystallization silicon carbide plate with good thermal conductivity and thermal shock resistance, widely used in daily-use ceramics, ceramic sanitary ware, microcrystalline glass, powder metallurgy, electronic ceramics, alumina ceramics, zirconia ceramics, flat or partition in high temperature flue, etc.

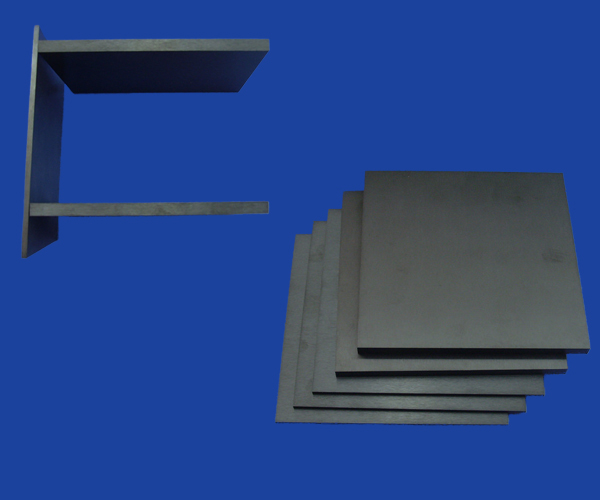

Can produce square board and circular board, all kinds of heterotypic plates, in addition we can according to user requirements to high temperature insulation shed board one-sided or two-sided glue coating processing.

SiC plates provide:

- Large plate capability

- Purity and grain size consistency

- Quick turn capability and precision grinding

We can also manufacture components from this material in sizes up to 450mm x 450mm, with thicknesses ranging from 0.5mm – 10mm thick.

Our industry leading technical ceramic engineers will work closely with customers to provide a product that meets their exacting standards.

Silicon Carbide Properties

|

|

|

Silicon Carbide Applications

|

Our Customers

OEM ceramic spare components and enjoys on-going relationships with businesses of all sizes in dozens of industries, in addition to the markets showcased at the top of this page, including:

§ Cable & Fiber Optics

§ Electric & Gas Welding Equipment

§ Electrical Apparatus & Wiring

§ Investment Casting

§ Infrared Equipment

§ Microwave Equipment

§ Refractory Furnaces

§ Thermocouples

§ Semiconductors

§ Soldering Equipment

§ Spare components for equipment parts

Ceramics offer many advantages compared to other materials. They are harder and stiffer than steel; more heat and corrosion resistant than metals or polymers; less dense than most metals and their alloys; and their raw materials are both plentiful and inexpensive. Ceramic materials display a wide range of properties which facilitate their use in many different product areas.

Aerospace:

space shuttle tiles, thermal barriers, high temperature glass windows, fuel cells.

Consumer Uses:

glassware, windows, pottery, Corning¨ ware, magnets, dinnerware, ceramic tiles, lenses, home electronics, microwave transducers.

Automotive:

catalytic converters, ceramic filters, airbag sensors, ceramic rotors, valves, spark plugs, pressure sensors, thermistors, vibration sensors, oxygen sensors, safety glass windshields, piston rings.

Medical (Bioceramics):

orthopedic joint replacement, prosthesis, dental restoration, bone implants.

Military:

structural components for ground, air and naval vehicles, missiles, sensors.

Computers:

insulators, resistors, superconductors, capacitors, ferroelectric components, microelectronic packaging.

Other Industries:

bricks, cement, membranes and filters, lab equipment

Communications: fiber optic/laser communications, TV and radio components, microphones...

Ceramic materials(include but not limited belows)

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL