E-mail:admin@cerampart.com

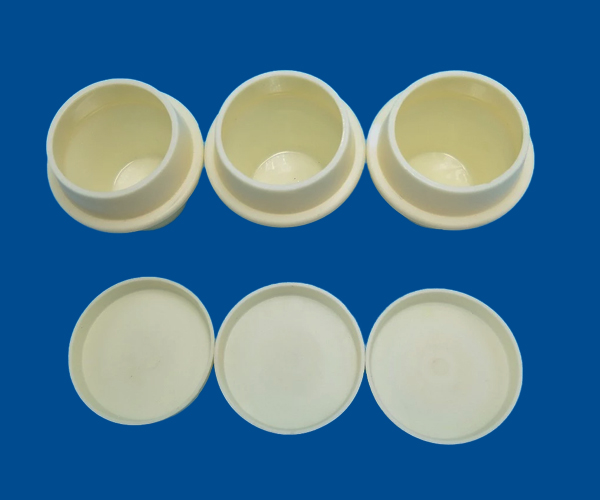

Ceramic Crucibles Heat Resistance Alumina Zirconia Ceramic Melting Crucible

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Ceramic Crucibles Heat Resistance Alumina Zirconia Ceramic Melting Crucible

High Quality, High Precision, Delivery on time, Factory Price

The ceramic crucible can be used below 1800 ºC (3272ºF). ceramic crucible has the advantages of high purity, high temperature resistance, large size, high precision, good thermal insulation, energy saving, stable quality and so on.

we can manufactuer or customized multi types high temperature resistung ceramic crucibles / boart/ tray, Cylindrical, Rectangular...etc

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

Generally, ceramic crucible cannot be used to melt NaOH, Na2O2, Na2CO3 and other basic substances as flux to avoid corrosion of porcelain crucible.Porcelain crucible cannot contact with hydrofluoric acid.

Produce and machining

1. Can Be Custom By Drawing Or The Parameter

2.Can Be Offer a Samples Within 1--10 Qty

3. The Shipping Time Of The Samples Within 2days

4. Quick Delivery Via Fedex,Dhl,Ups,Tnt Etc.

For more informations (the price,payment etc), Please contact us or email: admin@cerampart.com

Parts of us manufactuer the sizes of the crucible(not limited below)

Type 1: Cylinder ceramic crucible

| Outer diameter(mm) | Height(mm) | Wall thickness(mm) | Volume(ml) |

| 20 | 30 | 1.5 | 10 |

| 30 | 30 | 1.8 | 15 |

| 30 | 60 | 1.8 | 30 |

| 36 | 45 | 2.5 | 30 |

| 40 | 32 | 1.6 | 30 |

| 40 | 50 | 2.5 | 45 |

| 43 | 42 | 1.8 | 50 |

| 60 | 60 | 2.5 | 130 |

| 59 | 90 | 2.5 | 200 |

| 100 | 40 | 5.5 | 200 |

| 80 | 80 | 3.3 | 350 |

| 100 | 100 | 4.0 | 550 |

| 135 | 160 | 6.0 | 2000 |

Type 2: Cone-shape crucible

| Upper OD(mm | Bottom OD (mm) | Height(mm) | Wall thickness (mm) | Volume (ml) |

| 25 | 14 | 20 | 1.5 | 5 |

| 30 | 18 | 30 | 1.7 | 10 |

| 34 | 20 | 38 | 1.9 | 20 |

| 46 | 25 | 40 | 2 | 30 |

| 56 | 30 | 45 | 2.9 | 50 |

| 55 | 48 | 53 | 2.5 | 90 |

| 47 | 37 | 68 | 3.5 | 100 |

| 55 | 48 | 72 | 2.6 | 140 |

| 70 | 44 | 85 | 2.9 | 200 |

| 75 | 50 | 90 | 2.9 | 300 |

| 80 | 65 | 110 | 3.3 | 400 |

| 100 | 70 | 120 | 3.5 | 600 |

| 105 | 70 | 150 | 4.5 | 800 |

| 113 | 75 | 160 | 3.5 | 1200 |

| 125 | 80 | 155 | 3.5 | 1200 |

Type 3: Other shapes

| Shape | Length(mm) | Width(mm) | Height(mm) | Wall thickness(mm) | Volume(ml) |

| Rectangular | 27 | 23 | 10 | 2 | 5 |

| Rectangular | 97 | 17 | 12 | 2 | 7 |

| Rectangular | 60 | 30 | 15 | 2 | 20 |

| Rectangular | 100 | 20 | 20 | 2 | 25 |

| Square | 75 | 75 | 40 | 2.5 | 130 |

| Square | 85 | 85 | 40 | 3 | 200 |

| Rectangular | 155 | 120 | 55 | 5.5 | 550 |

| Square | 100 | 100 | 40 | 4 | 550 |

| Square | 160 | 160 | 78 | 6 .5 |

1400 |

Custom OEM will be shipped within 15 days after determining the parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the ceramic plates, please contact us or email:admin@cerampart.com

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL