E-mail:admin@cerampart.com

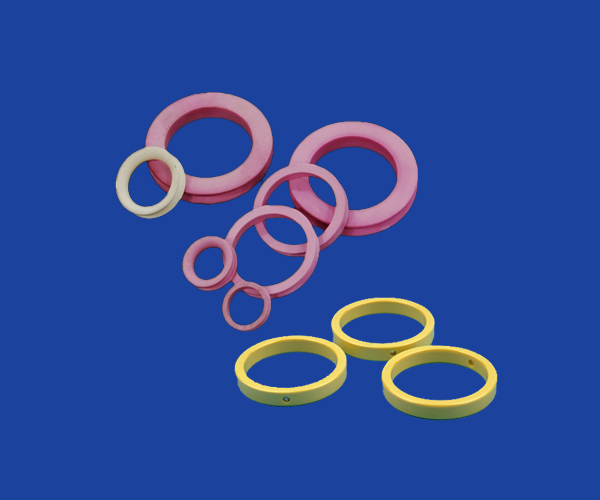

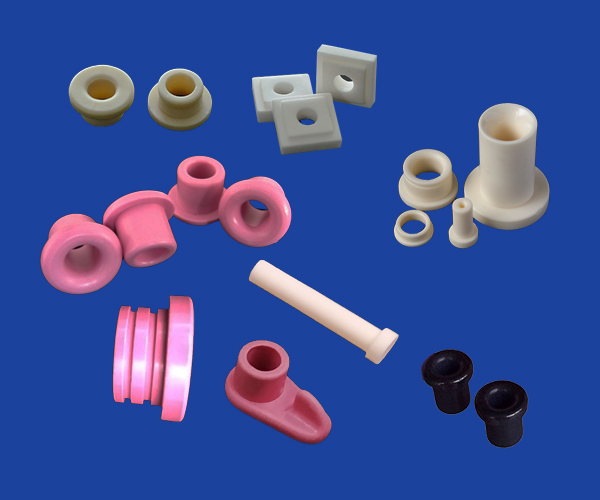

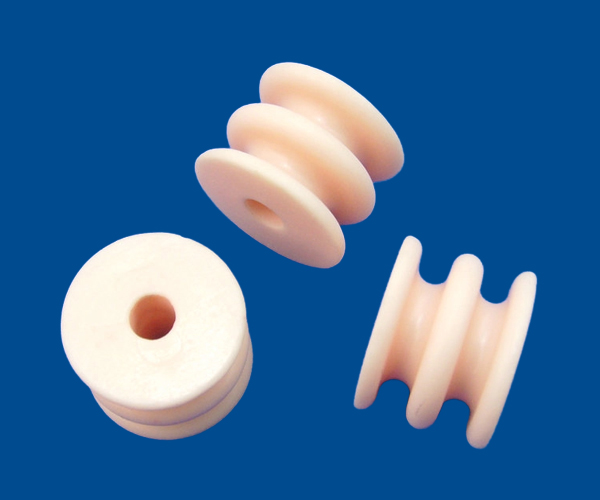

Ceramic eyelets wear abrasion resistance alumina zirconia ceramic eyelet guides

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Ceramic Eyelets Wear Abrasion Resistance Alumina Zirconia Ceramic Eyelet Guides

Ceramic Parts and components manufacturer,OEM

High Quality, High Precision, Delivery on time, Factory Price

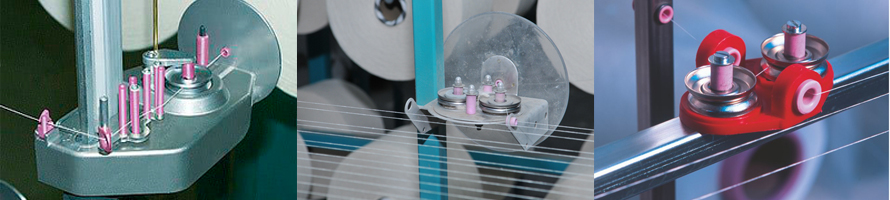

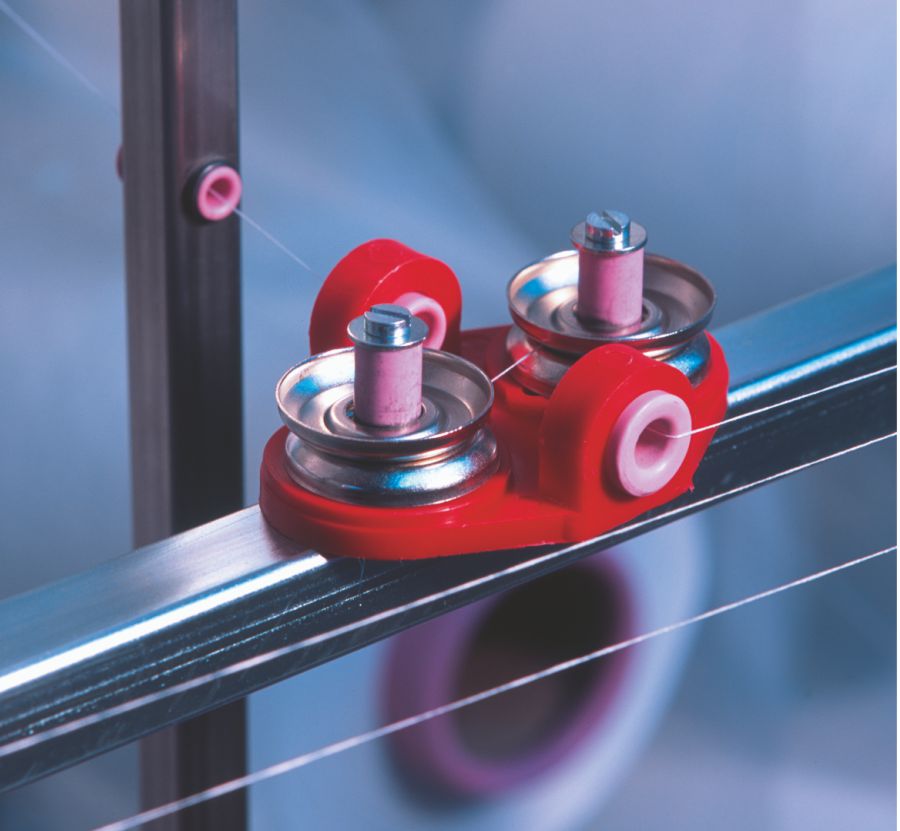

Ceramic eyelets is suitable for all kinds of wire winding machines and textile machinery in the wire parts.By precision ceramic processing, super fine polishing Ra0.2, due to high hardness, smooth surface, enameled wire in its smooth surface sliding without damage.

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

We can also polish the ceramic eyelet according to the users requirement, such as a surface finish with semi-polished (Ra 0.8) and fine polished (Ra 0.1).

The table below shows the commonly used specifications of ceramic eyelets.

Technical Specifications:

| D1 | D2 | d | H | H1 |

| 4.5 | 2.8 | 1.0 | 3.0 | 1.0 |

| 5.0 | 3.5 | 2.4 | 3.6 | 1.0 |

| 6.7 | 4.7 | 2.6 | 3.2 | 1.2 |

| 10.0 | 7.2 | 4.8 | 8.6 | 1.6 |

| 10.0 | 7.0 | 4.8 | 8.6 | 1.6 |

| 11.0 | 8.0 | 3.6 | 9.0 | 3.0 |

| 7.8 | 5.2 | 3.0 | 5.3 | 1.5 |

we also offer a hub grooving service for snap ring fitting onto the eyelet that you select. The minimum wall thickness of no thinner then 1.0 mm holds. Three groove widths are available, 1.1, 1.3 and 1.6 mm.

The other ceramic eyelets products:

|

|

|

|

| ceramic rollers, ceramic rolls, ceramic pulleys | ceramic eyelets, ceramic rings, ceramic loops, threaded ceramic eyelets | ceramic eyelet with flange, flanged eyelet, guide eyelet, flange bushing, flanged bush | pigtails, dogtails, hook guides, hooks with metal holder, with metal holder |

Notes of the ceramic eyelets usages:

ceramic eyelets for textile , wire and other ceramic sleeve tube hooks is best for textile wire equipments which have a high perfoamance like wear resistance , soomth, high temperature resistance etc features than metal materails parts.

The technical advantages of oxide ceramic thread guide components on the basis of Al2O3, TiO2 and ZrO2can be summarized as follows:

- High wear resistance in high-speed processes

- Accuracy of contours

- Optimally adjustable topography of the thread contact area depending on the application

- Low frictional losses

- Hardly any thread breakage

- No contact reactions with the thread

- Low thread abrasion

- With the use of TiO2 ceramic, no electrostatic charging.

- Reliability and long lifetime over years in the operating conditions

Excellent wear resistance, can improve the service life of textile equipment, ceramic material has a good surface smoothness, which can protect the textile wire line from damage。

| For more information about ceramics textile wire parts,please contact our engineers in time >>> |

|

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL