E-mail:admin@cerampart.com

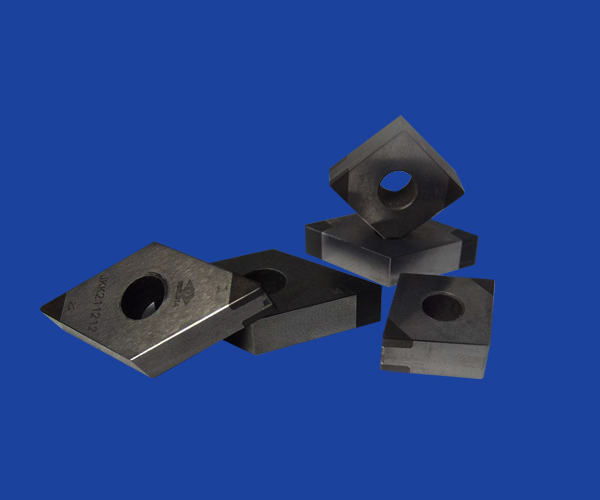

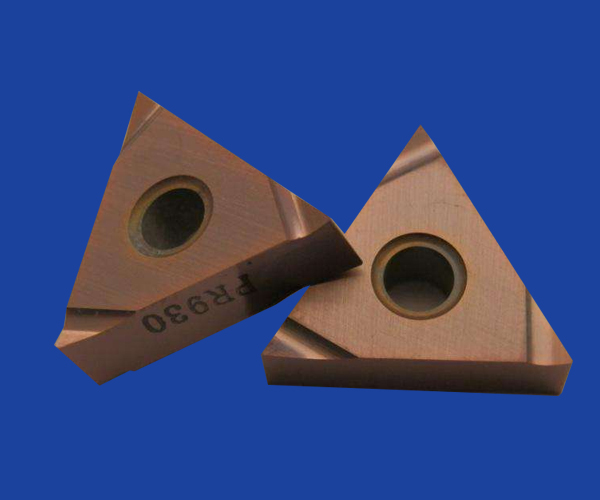

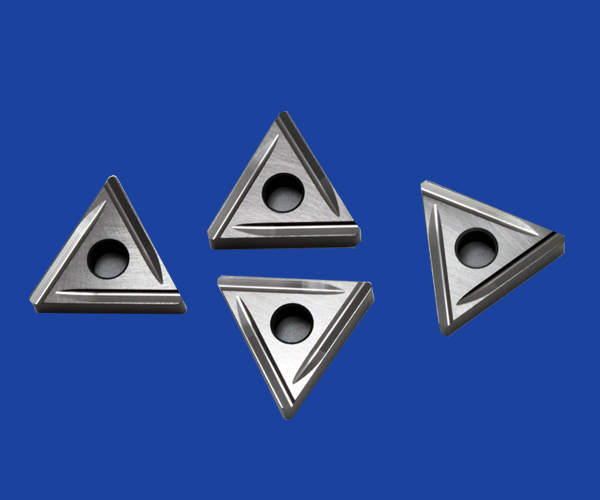

Ceramic Insert Cutting Mechanical Hardness Wear Heat Resistance Alumina Zirconia Ceramic Insert

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

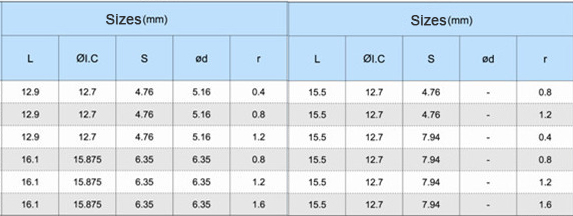

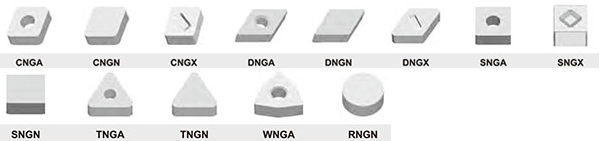

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Ceramic Insert Cutting Mechanical Hardness Wear Heat Resistance Alumina Zirconia Ceramic Insert

Ceramic Parts and components manufacturer,OEM

High Quality, High Precision, Delivery on time, Factory Price

Precision ceramic insert with ceramic high strength, high hardness, wear resistance, high temperature resistance, oxidation resistance and chemical stability and other characteristics, is a very important tool and structural materials, it has a small density, high hardness, wear resistance and good thermal conductivity, not because of sudden heat and brittle.

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

The property of the ceramic:

·Excellent physical & chemical stability ·High temperature resistance(up to1750℃)

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity..

Ceramic Insert precision process:

|

Ceramic Parameter:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of Ceramic Insert or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL