E-mail:admin@cerampart.com

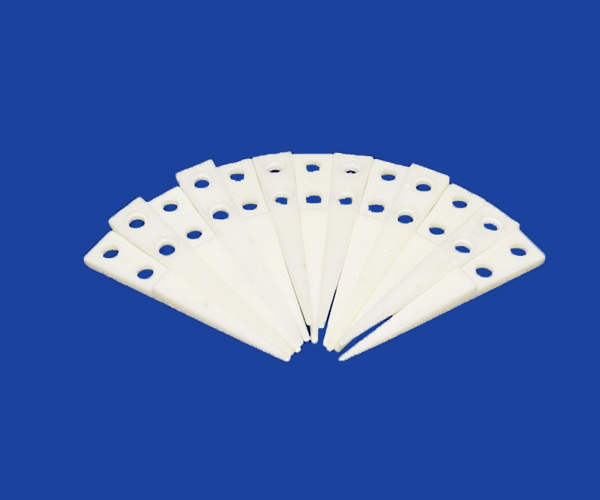

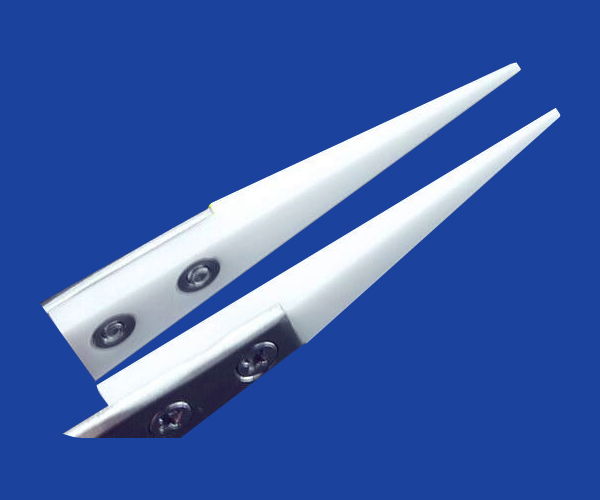

Ceramic tweezers tip with non-conductive and heat resistant precision replaceable tip tweezers in stocks

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Ceramic Tweezers Tip with Non-Conductive And Heat Resistant Precision Replaceable Tip Tweezers

Ceramic Parts and components manufacturer,OEM

High Quality, High Precision, Delivery on time, Factory Price

As a manufacturer of Tip Tweezers,us offers a full range of Technical Ceramic Tweezers Replaceable Tip Tweezers p and Tip Tweezers related products manufactured from technical ceramic materials.Outstanding ceramic properties improve your application.Now, popular size in stock and can be customized.

Outstanding ceramic properties:

·Excellent physical & chemical stability ·High temperature resistance

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity.

Types of the ceramic tweezrs:

point,curved,straight,replacement tips...

Parts of the us machinable ceramic tweezers tips specifiactions:

Straight, tips 1mm wide, serrated. Length: 5" (125mm)

Straight, tips 0.3mm wide, smooth, very fine. Length: 5" (125mm)

Curved, tips 1mm wide, smooth. Length: 5" (125mm)

Ceramic tip length 35mm. Tip width: 2mm. Length: 5¼" (134mm)

Ceramic tip length: 30mm. Tip width 0.3mm. Length: 5¼" (134mm)

Ceramic tip length: 33mm. Tip width 0.3mm. Length: 5¼" (134mm)

Ceramic tip length 40mm. Tip width 0.5mm. Length: 5¼" (134mm)

Ceramic tip length: 43.5mm. Tip width 0.6mm. Length: 5¼" (134mm)

Available tweezers in stocks:

| Tip Size (CTM) |

|

.038" X .04" .95mm X 1mm |

|

.038" X .04" .95mm X 1mm |

|

.035" X .08" .88mm X .2mm |

|

.035" X .08" .88mm X .2mm |

|

.015" X .06" .38mm X 1.5mm |

|

.015" X .06" .38mm X 1.5mm |

Feature:

- A superior combination of high strength and extreme hardness.

- Possesses relatively low density; no open porosity.

- Offers a very hard surface with good abrasion and wear resistance.

- Has good flexural strength and fracture toughness.

- Excellent thermal properties and high temperature stability.

- Extreme corrosion resistance, nearly chemically inert.

- Electrically insulating.

- Typically applications include soldering processes, handling of components during thermal and chemical processes. Generally these tweezers are used when very rigid tips are required.

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

Precision manufacturing:

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL