E-mail:admin@cerampart.com

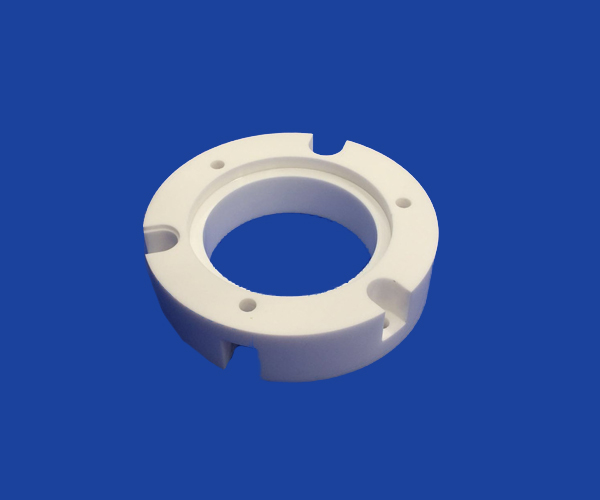

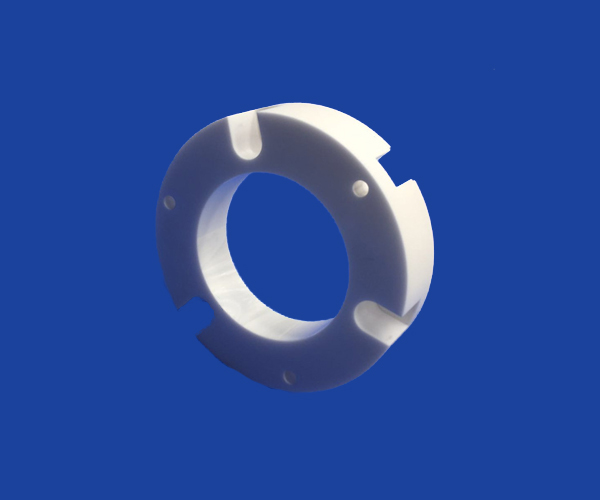

Insulation Ceramic Alumina Flange For Vacuum Environment

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Insulation Ceramic Alumina Flange For Vacuum Environment

The alumina Flanges application is for replacing SS flanges in vacuum when electrical insulation is needed.

This particular flange is a standard flange, the compressive stress applied on the ceramic will not break it.

There is a lot of applications where we could need this type of flange.

We can supply all kinds of the 95%, 99% and 99.5% alumina ceramic components, including the shape of tubes, sheet, pins, sleeves, rods, plates, rings, piston, spindle, roller, shaft, plunger, tubes, bushing, spool, block, insert, lining, peg, fixture, nozzle and other abnormity shape. The alumina ceramic half ring size can be made according to client's customized drawing.

Materials:

| Property | Alumina | Property | Zirconia |

| Bulk density(g/cm3) | 3.85-3.93 | The density (g/cm3) | 6.05 |

| Hardness(HRA≥) | 86 | Bibulous rate(%) | 0 |

| Bending strength(Mpa≥) | 300 | Thermal expansion coefficient(10-6 /k) | 10.5 |

| Maximum service temperature(℃) | 1500 | Young's modulus of elasticity(Gpa) | 210 |

| Linear expansion coefficient(×10-6/℃) | 7.15-7.67 | Poisson's ratio(/) | 0.3 |

| Dielectric constant(εr(20℃,1MHz)) | 9.21 | Hardness (MPa) | 1200 |

| Dielectric loss(tanδ×10-4,1MHz) | 2.5 | Bending strength (MPa) | 950 |

| Volume resistivity(Ω·cm(100℃)) | 9.2*1016 | The bending strength (MPa) | 210 |

| The compressive strength(Mpa≥) | 2500 | Compressive strength (MPa) | 2000 |

| Flexural strength(Mpa≥) | 200 | Fracture toughness(Mpa.m1/2) | 10 |

| Modulus of elasticity(Gpa) | 300 | Thermal conductivity (W/m.k) | 2 |

| Poisson's ratio | 0.2 | Specific resistivity(Ω.mm2/m) | >1015 |

| Thermal conductivity Coefficient(W/m·K(20℃)) | 20 | Maximum service temperature(℃) | 1350 |

| Dc breakdown strength | 43.7 | Acid and alkali corrosion resistance(/) | strength |

| Tensile seal strength(Mpa) | 104.4 |

|

Properties :

1. High Hardness wear resistance

2. High precision 3. Good mechanical strength 4. High temperature and chemical resistance 5. Electric insulation 6. Low thermal expansion 7. Smooth surface finish 8. Thermal Shock Resistance Material :

1. Alumina ceramic

2. Zirconia ceramic 3. Silicone carbide 4. Silicone nitride Lead-time: 20-30 days for mass production, 7-15 days for samples. |

||||||||||||||||||||||||

Us can be based on customer drawings and requirements to provide non-standard ceramic accessories and provide related solutions.

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL