E-mail:admin@cerampart.com

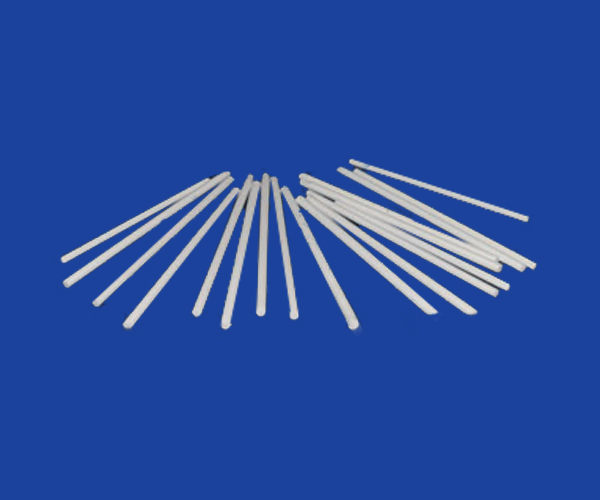

Alumina Ceramic Needle Gauge High Precision Ceramic Pin Gauge Zirconia Pin Gauges

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Alumina Ceramic Needle Gauge

Alumina ceramic needle gauge is based on the current testing equipment used in the tungsten steel needle regulation of poor corrosion resistance, short life defects, as well as the white steel needle gauge connection is not reliable, easy to rust and fragmentation of the status quo and developed high-tech products.

Alumina ceramic needle gauge characteristics are: With the media contact surface and working face are alumina ceramic needle gauge, no special protection is required. With the existing ceramic needle gauge ratio, with anti-embroidery, can washed, corrosion resistance, high strength characteristics, at the same time alumina ceramic needle gauge service life is 10 times times higher than tungsten steel white steel needle gauge, but also can improve the life of sealing filler, with a very high wear resistance, corrosion resistance, impact resistance characteristics.

|

Properties :

1. High Hardness wear resistance

2. High precision 3. Good mechanical strength 4. High temperature and chemical resistance 5. Electric insulation 6. Low thermal expansion 7. Smooth surface finish 8. Thermal Shock Resistance Material :

1. Alumina ceramic

2. Zirconia ceramic 3. Silicone carbide 4. Silicone nitride Lead-time: 20-30 days for mass production, 7-15 days for samples. |

||||||||||||||||||||||||

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL