E-mail:admin@cerampart.com

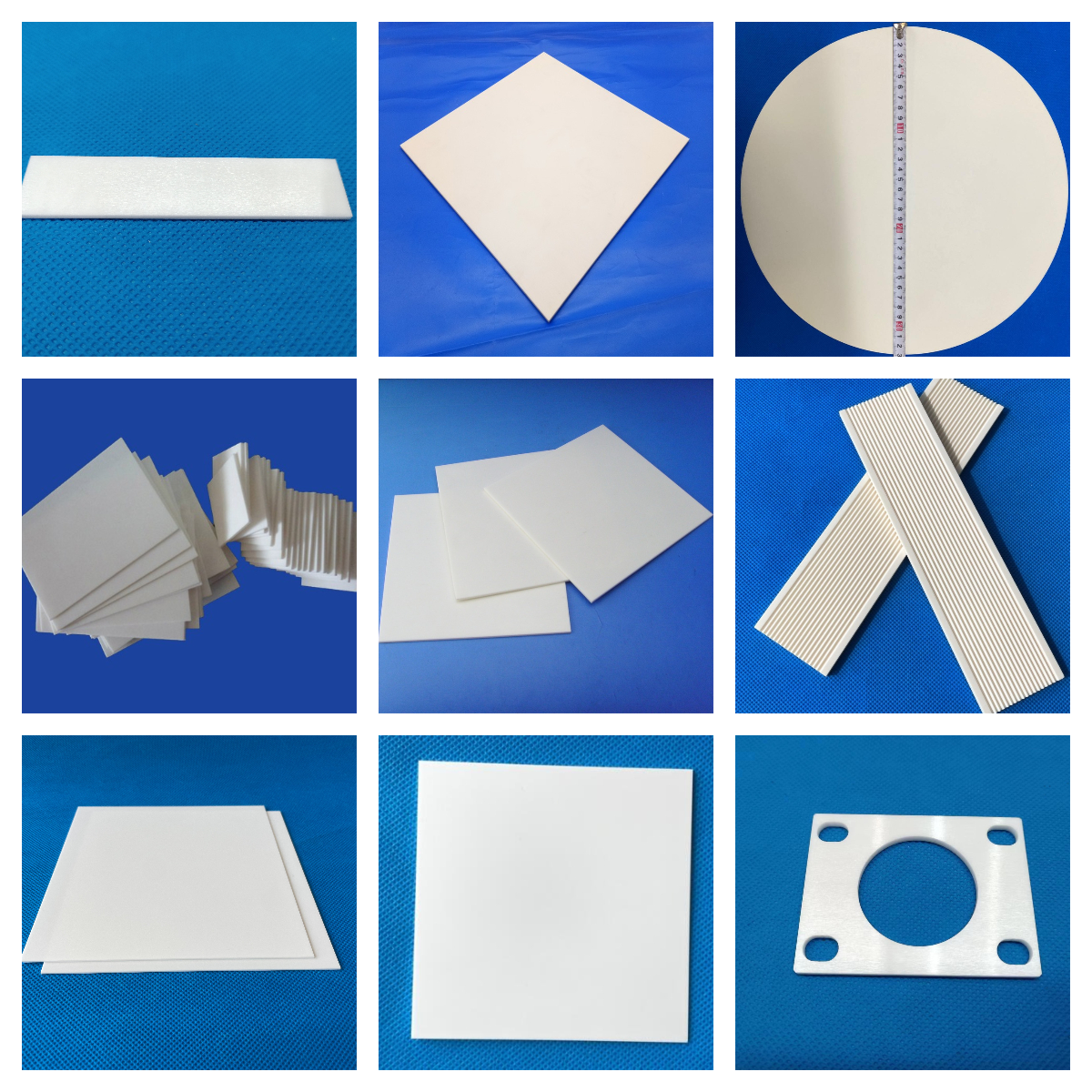

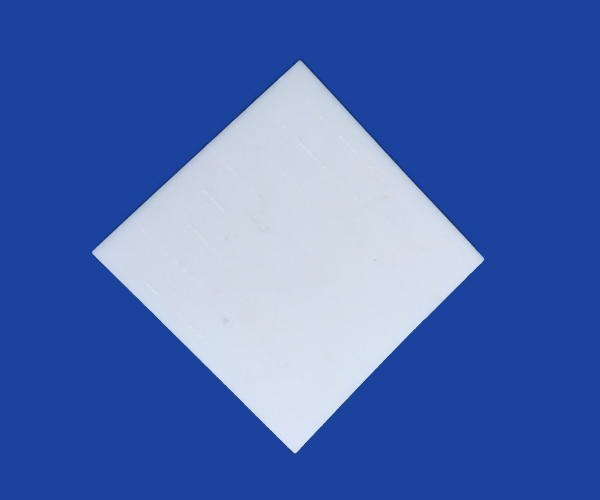

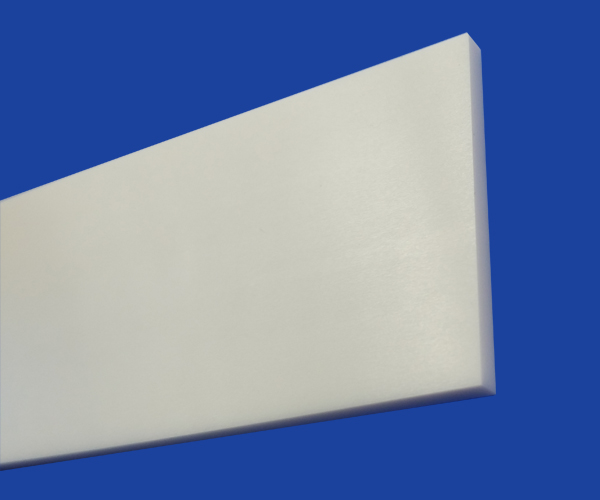

Thin 0.2-15mm Length 10-400mm Width 10-400mm Alumina Zirconia Ceramic Plate Sheet Substrate Discs

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Max Length/width:450mmThickness:0.2mm...

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Thin 0.2-15mm Length 10-400mm Width 10-400mm 95%~99.99% Alumina, Zirconia, ZTA, SSiC, and Si3N4 Ceramic Plate/Sheet/Substrate/Discs

Through high-temperature sintering (usually above 1500°C) and optimized processes, the density of the ceramic plate can reach 95%~99.99% of the theoretical density, significantly improving the mechanical strength and corrosion resistance of the material.

|

The best-selling sizes are as follows in stock: Ceramic plates sheet substrate disc series: |

Shape: square, round, oval, flat, strip, porous, irregular, etc

Customization

For the other sizes and shapes, we can offer a customization. please send the details or files to our official e-mail: admin@cerampart.com

Applications of alumina and zirconia ceramic cermaic plate/sheet/disc/substrates:

|

User industries: Automotive, aviation, space travel Electrical and thermal insulation Electronics and sensors Energy technology, power generation Environmental technology Fluid technology Friction-reduction, wear- and corrosion -protection High temperature applications Laboratory technology Laser technology Mechanical and chemical process engineering Metal industry Optics Semiconductor processing equipment Surface treatment Vacuum technology Other industries |

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength, Wear Resistance Up To Mohz 9.0; HRA 80-90...

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Thermal conductivity

10. Other excellent property

|

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic sheet,plates,block or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL