E-mail:admin@cerampart.com

Ceramic Locating Pins Si3n4 Silicon Nitride Welding Guide Heat-Resistant And Non-Conductive Ceramic Pin

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Mini-OD: 0.02mm;Max-length: 500mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Ceramic Locating Pins Si3n4 Silicon Nitride Welding Guide Heat-Resistant And Non-Conductive Ceramic Pin

OEM And Custom The Ceramic Parts And Components With Your Drawing Or Demand

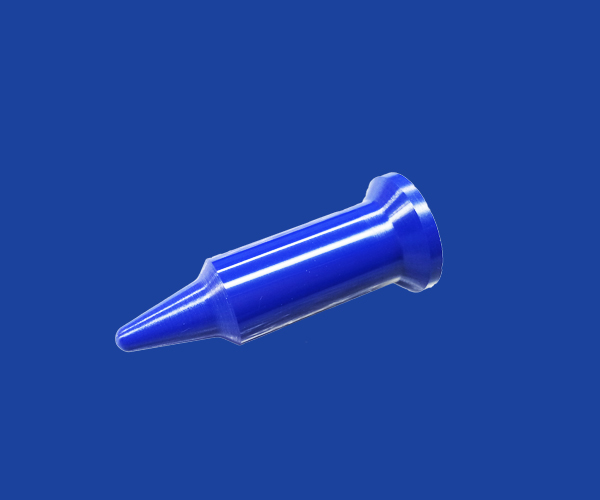

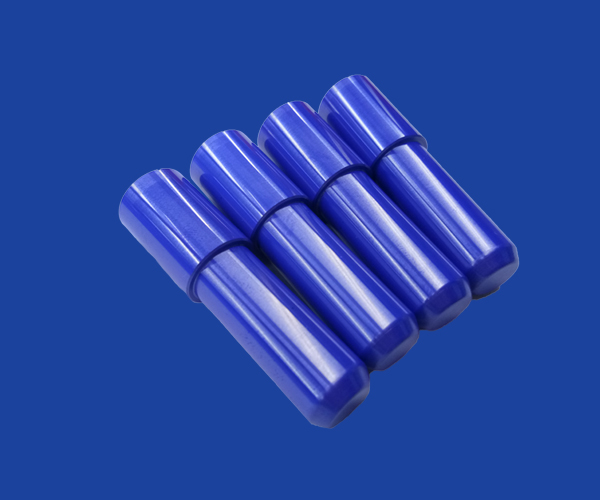

Ceramic Locating Pins

Locating pins for Nut welding are produced with several different materials and several different coatings. Generally speaking, the more costly the pin, the “longer life” it has in production. As a long time distributor of resistance welding supplies, we stock commonly used pins at competitive prices.

Silicon Nitride Ceramic is typically used to make welding guide rolls for the high frequency ERW in continuous steel tube & aluminium tube production. Si3N4 is an excellent material solution in this application because of its following advantages:

| · Flexural strength | · Chemical resistance | · Electrical insulation | · Corrosion resistance | · Dielectric strength |

| · Wear resistance | · Temperature resistance | · Thermal conductivity | · High voltage | · Hardness... |

Location And Resistance Weld Centering Pins

The heat-resistant and non-conductive ceramic pin materials help achieve consistency over hundreds of thousands or millions of welds, without the need for constant downtime and replacement.

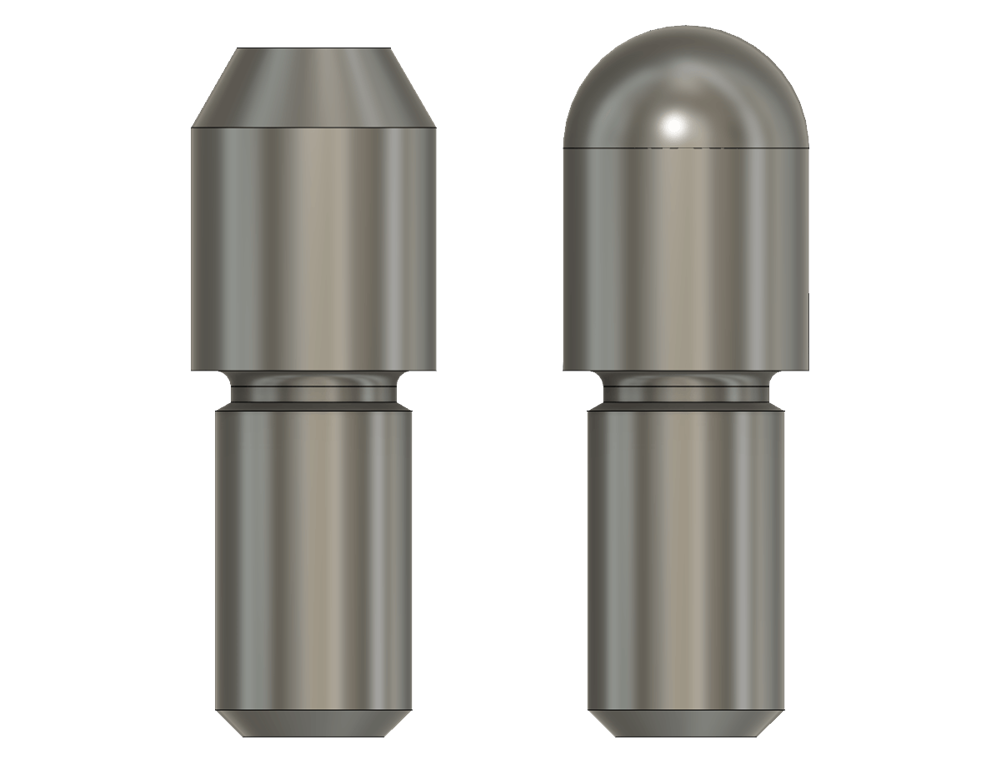

The weld pins are available in three standard noses, for automatic feeders or hand-fed applications, with standard diameters to 0.1 mm stamping hole diameter.

Part of us manufacturer pins:

| NUT SIZE | A | C | E | F | G |

|---|---|---|---|---|---|

| M4 | 3 | 12 | 4.8 | 6.5 | 12.0 |

| M5 | 3 | 12 | 5.8 | 7.5 | 12.0 |

| M6 | 5 | 12 | 6.8 | 9.5 | 13.9 |

| M8 | 6 | 14 | 7.8 | 9.5 | 13.9 |

| M8 | 6 | 14 | 8.8 | 8.0 | 13.9 |

| M8 | 6 | 14 | 9.0 | 7.5 | 13.9 |

| M10 | 7 | 16 | 10.2 | 8.0 | 13.9 |

| M10 | 7 | 16 | 10.7 | 8.0 | 13.9 |

| M12 | 8 | 18 | 14.4 | 8.0 | 13.9 |

| M12 | 8 | 18 | 11.6 | 8.0 | 13.9 |

Tips: avaible in stocks part of above, and can be customized

|

Small Head Pins

Small head locating pins are typically smaller than the pin's shoulder, which is 22 or 25mm in diameter. The NAAMS Standards pin diameter sizes for small heads are 6mm, 8mm, 10mm, 12mm, 13mm, 16mm, and 19mm. |

|

Large Head Pins Large head locating pins have heads wider than the insert bases which is a diameter of 15.98mm. The standard sizes for large heads are offered in 25mm, 30mm, 35mm, and 40mm. |

|

Retractable Pins All retractable pins come with a slotted hole meant for an 8mm socket head shoulder screw assembly. The standard offerings are the same as the small heads and large heads but retractable locating pins do not come with shoulders because of the added slot and hole configuration. |

|

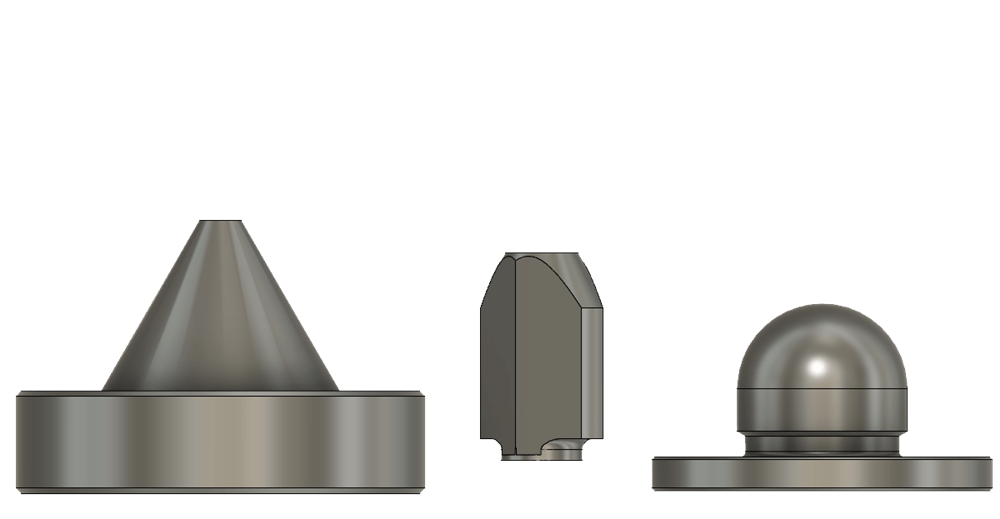

Bullet Nose Pins, Diamond Pins, and Cone Pins Bullet nose and cone pins come as 4-way and 2-way pins like diamond pins. They work as 4-way pins by restricting the motion from 2 different axis, stopping the located part in 4 separate directions. This helps to keep your workpieces in place during the automation or manufacturing process. As 2-way pins, they come with two slits and the diamond pins come with a diamond shaped head. This limits the free motion to only 1 axis or 2 degrees of movement. Using a configuration of both 2 and 4-way pins help to hold workpieces in the desired place. |

|

Round and Sphere Pins Round and sphere pins are the most common and come as a 4-way. Though they are most common, they can present problems suck as binding the workpiece. It is recommended to use them in conjunction with 2-way pins. |

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic pins or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL