E-mail:admin@cerampart.com

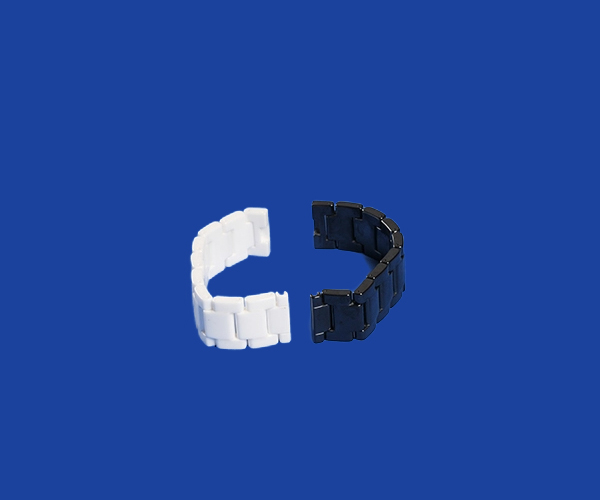

Custom Watch Belt Ceramic Watchband Watchstrap Wristband

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Custom Watch Belt Ceramic Watchband Watchstrap Wristband

Description:

Color: can be customized

Material: Ceramic

14mmLength(clasp closed):17cm

16mmLength(clasp closed):16.5cm

18mmLength(clasp closed):17.5cm

And others sizes

Feature:

- The watchband is standard style, can fit most watches.

- High quality ceramic with stainless steel clasp is skin-friendly without allergy concerns.

- Great replacements for the old watch bands as a spare, or as a gift.

There are 3 main directions in the application of zirconia ceramics in intelligent wearable equipment.

1.the most important use is ceramic mobile phone cover, since the introduction of the AppleWatch in 2015, for the first time using zirconia ceramics as cover appearance, leading the entire back of the trend of the market, at present, HUAWEI, millet mobile phone has a variety of ceramic cover, and substantial sales, not to be part of the ceramic cover mobile phone preferred.

2.use as fingerprints.

3. wearable equipment shell, is also the first source to AppleWatch, currently including Samsung, a variety of watches, bracelets are used zirconia shell, because of many advantages of zirconia ceramics: the first is to wear waterproof, secondly is not shielded signal, third is the appearance of zirconia ceramics after grinding and diamond shining.

Materials:

| Property | Alumina | Property | Zirconia |

| Bulk density(g/cm3) | 3.85-3.93 | The density (g/cm3) | 6.05 |

| Hardness(HRA≥) | 86 | Bibulous rate(%) | 0 |

| Bending strength(Mpa≥) | 300 | Thermal expansion coefficient(10-6 /k) | 10.5 |

| Maximum service temperature(℃) | 1500 | Young's modulus of elasticity(Gpa) | 210 |

| Linear expansion coefficient(×10-6/℃) | 7.15-7.67 | Poisson's ratio(/) | 0.3 |

| Dielectric constant(εr(20℃,1MHz)) | 9.21 | Hardness (MPa) | 1200 |

| Dielectric loss(tanδ×10-4,1MHz) | 2.5 | Bending strength (MPa) | 950 |

| Volume resistivity(Ω·cm(100℃)) | 9.2*1016 | The bending strength (MPa) | 210 |

| The compressive strength(Mpa≥) | 2500 | Compressive strength (MPa) | 2000 |

| Flexural strength(Mpa≥) | 200 | Fracture toughness(Mpa.m1/2) | 10 |

| Modulus of elasticity(Gpa) | 300 | Thermal conductivity (W/m.k) | 2 |

| Poisson's ratio | 0.2 | Specific resistivity(Ω.mm2/m) | >1015 |

| Thermal conductivity Coefficient(W/m·K(20℃)) | 20 | Maximum service temperature(℃) | 1350 |

| Dc breakdown strength | 43.7 | Acid and alkali corrosion resistance(/) | strength |

| Tensile seal strength(Mpa) | 104.4 |

|

Properties :

1. High Hardness wear resistance

2. High precision 3. Good mechanical strength 4. High temperature and chemical resistance 5. Electric insulation 6. Low thermal expansion 7. Smooth surface finish 8. Thermal Shock Resistance Material :

1. Alumina ceramic

2. Zirconia ceramic 3. Silicone carbide 4. Silicone nitride Lead-time: 20-30 days for mass production, 7-15 days for samples. |

||||||||||||||||||||||||

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL