E-mail:admin@cerampart.com

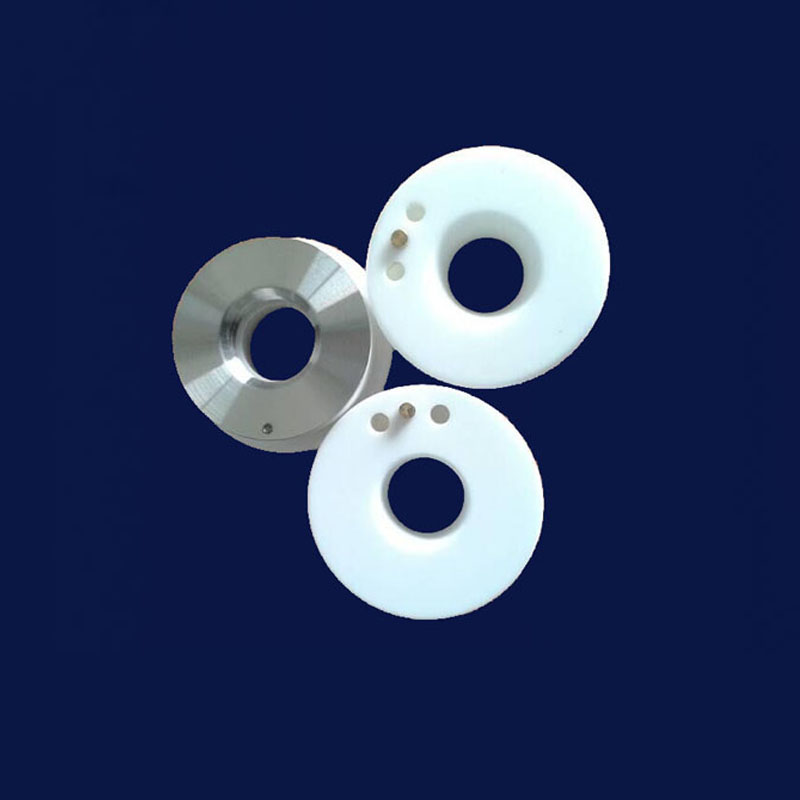

Ceramic Ring Industrials Machinable

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Ceramic Ring Industrials Machinable

Ceramic material, as an inorganic non-metallic material, has many properties that metal materials do not have, such as: high strength, high hardness, high elastic modulus, high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, heat shock resistance.

Ceramic Ring is a solid Ceramic gasket that has been processed into octagonal or oval shaped solid Ceramic with a radial self-sealing effect.Ceramic Ring are in contact with the inner and outer sides (mainly the outer sides) of the flange trapezoidal groove as well as formed as seals by compression.

Ceramic Ring are divided into octagonal ring gaskets and elliptical gaskets.The metal ring gasket is divided into octagonal and elliptic structures according to the section shape.

Ceramic Ring and flange groove match, the main performance of surface contact.With elliptic annulus gasket photograph is compared, although not easy and flange groove achieves close close, but can use again, and because section is formed by straight line, easy machining.Elliptic ring gasket in flange groove is the line contact, sealing is good, but the processing accuracy requirements are high, thus increasing the manufacturing cost, at the same time the elliptic ring gasket can not be reused.

Product advantage

1. Chemical corrosion resistance

2. Fall resistance

3. Wear resistance

4. High temperature resistance

5. Anti-static

6. Fire resistance

Ceramic ring as ring pad of new material.Can be processed into different specifications of the ring ring.

Ceramic ring machining:

Cylindricity up to 0.004mm, linear tolerance up to 0.001mm, dimensional accuracy up to 0.001mm, thread minimum machinable internal thread M2, thickness up to 0.02mm, concentricity up to 0.003mm, minimum aperture up to 0.07mm...And other parameter...

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

Ceramic ring as ring pad of new material.Can be processed into different specifications of the ring ring.

Ceramic ring machining:

Cylindricity up to 0.004mm, linear tolerance up to 0.001mm, dimensional accuracy up to 0.001mm, thread minimum machinable internal thread M2, thickness up to 0.02mm, concentricity up to 0.003mm, minimum aperture up to 0.07mm...And other parameter...

Ceramic washer material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Shape : Round , square etc

Available color : black , white , yellowish etc

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL