E-mail:admin@cerampart.com

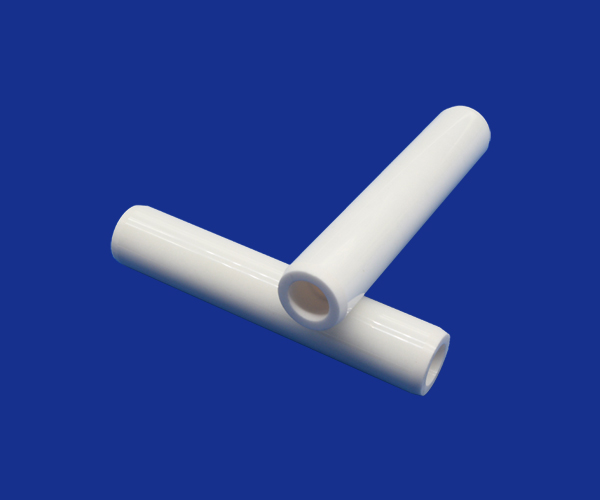

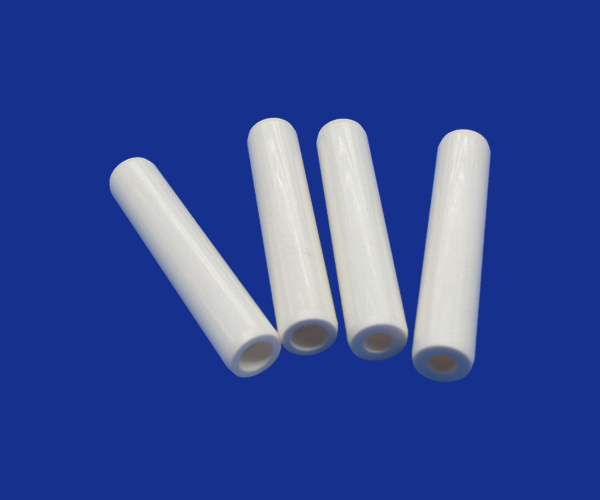

Hollow ceramic tubes

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Mini ID:0.3mm;Mini length:0.5mm;Max length: 400mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Hollow Ceramic Tubes High Temperature And Pressure Resistance Alumina Zirconia Tubes

Hollow ceramic tube is a kind of single-hole ceramic tube.The shape of inner hole of hollow pipe is generally different according to different application fields.Market industry commonly used, circular, square, triangle, polygon, irregular and so on.In fact, hollow ceramic tubes will be used as industrial accessories, and metal welding, adhesion, socket and other components of industrial products.

Hollow ceramic tube has the advantages of high melting point and boiling point, high hardness, insulation at normal temperature, and electrical conductivity at high temperature.

Advantages:

1. Refractory.

2. Self Lubricating

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Due to these outstanding properties, Ceramic Products are used in a wide range of industrial and advanced appications.

And a lot of practical applications prove that our ceramic products has reached a state of high standard and quality.

|

Dimension and Tolerance: · Diameter as small as 0.2mm, depends on length · Length as long as 500mm, as short as 0.5mm · Diameter tolerance we could make as fine as 0.001mm Ceramic material composition: · 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)... Type of hollow ceramic tube: Single hole, two hole, four hole, according to the customer's actual application requirements to determine the number of holes and the proportion of holes, hole shape. |

|

Part sizes of the hollow ceramic tubes in stocks:

| Length Range | Length Range | Outside Diameter | Outside Diameter | Inside Diameter | Inside Diameter |

| 4.000-6.875 in | 102-174 mm | 0.031 in | 0.79 mm | 0.005 in | 0.13 mm |

| 6.876-12.875 in | 175-327 mm | 0.031 in | 0.79 mm | 0.005 in | 0.13 mm |

| 12.876-18.875in | 328-479 mm | 0.031 in | 0.79 mm | 0.005 in | 0.13 mm |

| 4.000-6.875 in | 102-174 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 12.876-18.875in | 328-479 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 18.876-24.875in | 480-631 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.156 in | 3.96 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 6.876-12.875 in | 175-327 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 12.876-18.875in | 328-479 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 18.876-24.875in | 480-631 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.047 in | 1.19 mm |

| 4.000-6.875 in | 102-174 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 6.876-12.875 in | 175-327 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 12.876-18.875in | 328-479 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 18.876-24.875in | 480-631 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 12.876-18.875in | 328-479 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

| 4.000-6.875 in | 102-174 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

The related hollow ceramic tube:

single-hole ceramic tubes, porous ceramic tubes, irregularly porous ceramic tubes,ceramic tube insulator,ceramic tube heater...

As a ceramic manufacturer, we support the customization and machinable of ceramic tubes.Customized according to the special needs of customers.

These tubes find applications in a wide range of markets including:

Aerospace – we provide small notched rods used in the production of ceramic cores. For more information on ceramic cores, please visit our core section via the related links to the right.

Medical – our custom tubing is used for instrument and measuring apparatus.

Electrical – our range of resistor tubes, capacitor sleeves, insulating tubes, bushings and thermocouple tubes are widely utilised within this market.

and other industry or machine applications.

Our Customers

OEM ceramic spare components and enjoys on-going relationships with businesses of all sizes in dozens of industries, in addition to the markets showcased at the top of this page, including:

§ Cable & Fiber Optics

§ Electric & Gas Welding Equipment

§ Electrical Apparatus & Wiring

§ Investment Casting

§ Infrared Equipment

§ Microwave Equipment

§ Refractory Furnaces

§ Thermocouples

§ Semiconductors

§ Soldering Equipment

§ Spare components for equipment parts

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL