E-mail:admin@cerampart.com

Ceramic dosing pumps with alumina zirconia ceramic dosing pump/ valve

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Mini ID:0.3mm;Mini length:0.5mm;Max length: 400mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

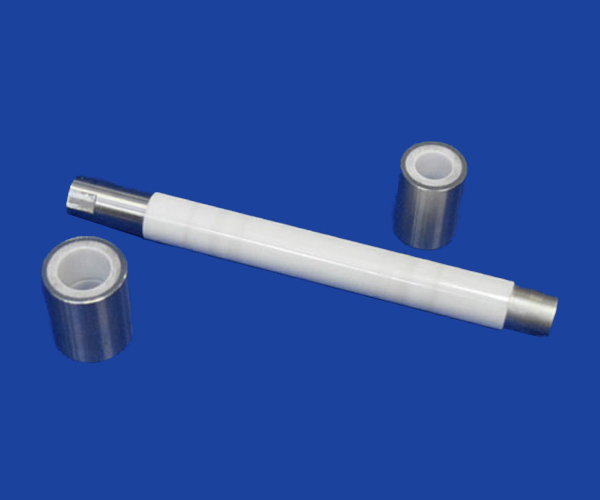

Ceramic dosing pumps acid chemical and high temperature resistance alumina zirconia ceramic pump/ valve

High precision Alumina Zirconia Ceramic Pump/ Valve OEM

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

US offers a wide variety of Ceramic dosing pumps manufactured from high-performance technical ceramic materials, including alumina, zirconia, and silicon carbide. Enhance performance and product life by using the material best suited to your application.

Ceramic can be used under 1800 ℃ high temperature environment.has excellent chemical stability under high temperature, is not easy to oxidize, and has good corrosion resistance to acid, alkali and salt.

Pump components

| Plunger shaft rod | Diameter (D:3-35mm) |

| Length (L:20-650mm) | |

| Can be machining thread,polishing,connecting metal part | |

| Sleeve pump body | Inside Diameter as small as 0.3 mm |

| Longth as long as 400mm, as short as 0.5mm | |

| Inside Diameter tolerance we could make as fine as 0.002mm | |

| Outside Diameter tolerance as fine as 0.001mm | |

| Wall thickness:0.5-15mm | |

| Pump head | Can be customized |

| Sealing rings | Can be customized |

| Metal parts | Can be customized |

Applications

Medical Equipment

Electronic Manufacturing

Pilot Plants

Environment Pollution Control

Precision Cleaning

Automotive

Food & Dairy

Spraying Systems

Cosmetic & Hygiene

R & D Laboratories etc

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL