E-mail:admin@cerampart.com

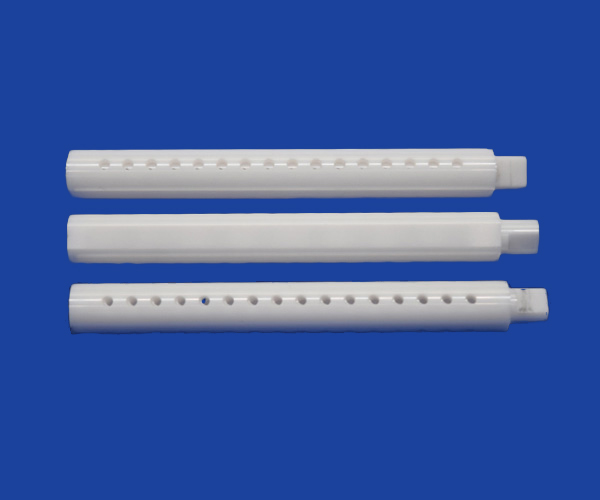

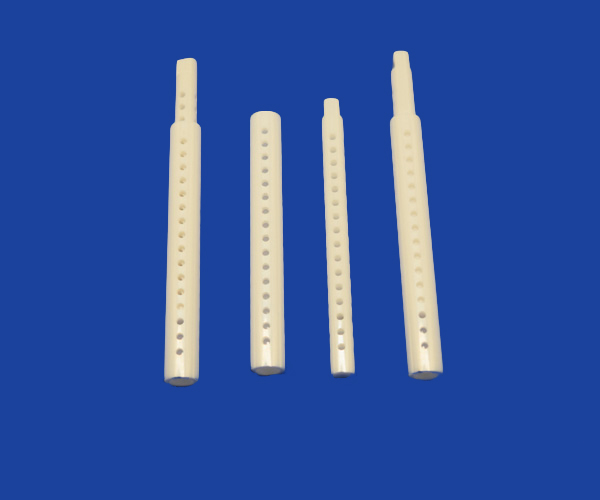

16 Needle Ceramic Dispensing Valve

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

16 Needle Ceramic Dispensing Valve

16 Needle Ceramic Dispensing sing Valve is a 16-pin hole design, advanced Ceramic material of high composition such as zirconia or alumina.It has good abrasion resistance, high hardness, high temperature resistance, non-stick and other properties.

16 Needle Ceramic Dispensing sing Valve is suitable for highly precise and repeatable applications.Depai quantitative valve has a variety of different series and sizes for customers to choose, a wide range of choices, in a variety of different industries in the application of quantitative processing, coating a variety of different materials, such as automotive parts on the glue, oil injection, or coated with silicone.

Ceramic Dispensing sing Valve has three different designs that can handle various Ceramic types of materials of varying viscosity from low to high, such as glue, sealant, grease, lubricating oil, silicone, etc.Ceramic Dispensing sing sing Valve is all pneumatic control, with the Ceramic Dispensing volume ranging from 0, 0.001ml to 100ml.In order to ensure that the material is accurately coated on the workpiece, a specially designed fixture will be equipped.

Materials parameter:

16 Needle Ceramic Dispensing sing Valve is a 16-pin hole design, advanced Ceramic material of high composition such as zirconia or alumina.It has good abrasion resistance, high hardness, high temperature resistance, non-stick and other properties.

16 Needle Ceramic Dispensing sing Valve is suitable for highly precise and repeatable applications.Depai quantitative valve has a variety of different series and sizes for customers to choose, a wide range of choices, in a variety of different industries in the application of quantitative processing, coating a variety of different materials, such as automotive parts on the glue, oil injection, or coated with silicone.

Ceramic Dispensing sing Valve has three different designs that can handle various Ceramic types of materials of varying viscosity from low to high, such as glue, sealant, grease, lubricating oil, silicone, etc.Ceramic Dispensing sing sing Valve is all pneumatic control, with the Ceramic Dispensing volume ranging from 0, 0.001ml to 100ml.In order to ensure that the material is accurately coated on the workpiece, a specially designed fixture will be equipped.

Materials parameter:

| Property | Alumina | Property | Zirconia |

| Bulk density(g/cm3) | 3.85-3.93 | The density (g/cm3) | 6.05 |

| Hardness(HRA≥) | 86 | Bibulous rate(%) | 0 |

| Bending strength(Mpa≥) | 300 | Thermal expansion coefficient(10-6 /k) | 10.5 |

| Maximum service temperature(℃) | 1500 | Young's modulus of elasticity(Gpa) | 210 |

| Linear expansion coefficient(×10-6/℃) | 7.15-7.67 | Poisson's ratio(/) | 0.3 |

| Dielectric constant(εr(20℃,1MHz)) | 9.21 | Hardness (MPa) | 1200 |

| Dielectric loss(tanδ×10-4,1MHz) | 2.5 | Bending strength (MPa) | 950 |

| Volume resistivity(Ω·cm(100℃)) | 9.2*1016 | The bending strength (MPa) | 210 |

| The compressive strength(Mpa≥) | 2500 | Compressive strength (MPa) | 2000 |

| Flexural strength(Mpa≥) | 200 | Fracture toughness(Mpa.m1/2) | 10 |

| Modulus of elasticity(Gpa) | 300 | Thermal conductivity (W/m.k) | 2 |

| Poisson's ratio | 0.2 | Specific resistivity(Ω.mm2/m) | >1015 |

| Thermal conductivity Coefficient(W/m·K(20℃)) | 20 | Maximum service temperature(℃) | 1350 |

| Dc breakdown strength | 43.7 | Acid and alkali corrosion resistance(/) | strength |

| Tensile seal strength(Mpa) | 104.4 |

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL