E-mail:admin@cerampart.com

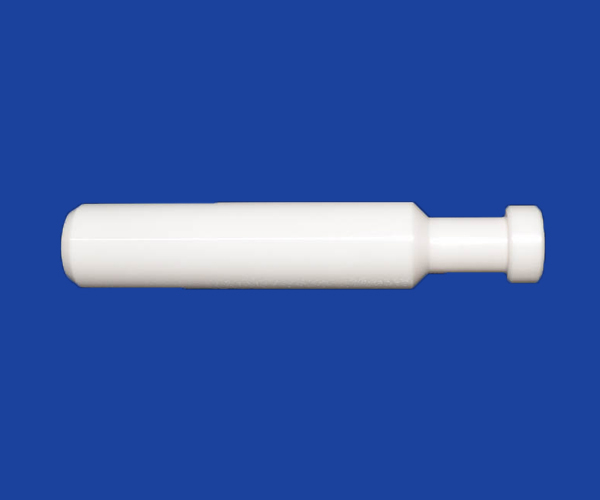

Alumina ceramic rod bar insulator heater threaded precision ceramic rods

- Brand:Mingrui Ceramic

- Material:Alumina ceramic

- Precision:0.001mm

- Features:Heat resistance High purity

- Color:White Blue Ivory Black etc.

- Customized:YES OEM

Alumina Ceramic Rod Bar Insulator Heater Threaded Precision Ceramic Rods

High precision Alumina Ceramic Parts

We can supply alumina ceramic rod of different specifications.Alumina ceramic rod is made of different proportions of high purity alumina from high-performance technical ceramic materials. Enhance performance and product life by using the material best suited to your application.

High purity alumina ceramics:

99.99% Alumina ceramic; 99.9% Alumina ceramic

Ordinary alumina ceramics:

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic.

Part of us machining case specifications:

| OuterDiameter (Inch) | Outer Diameter (mm) | Maximum Length |

| 0.137 | 3.48 | 36in / 914mm |

| 0.188 | 4.78 | 36in / 914mm |

| 0.197 | 5.00 | 36in / 914mm |

| 0.212 | 5.38 | 36in / 914mm |

| 0.250 | 6.35 | 36in / 914mm |

| 0.264 | 6.71 | 36in / 914mm |

| 0.313 | 7.95 | 36in / 914mm |

| 0.375 | 9.53 | 36in / 914mm |

| 0.388 | 9.86 | 36in / 914mm |

| 0.4 | 10.16 | 36in / 914mm |

| 0.44 | 11.18 | 36in / 914mm |

| 0.500 | 12.70 | 36in / 914mm |

| 0.518 | 13.16 | 36in / 914mm |

Secifications of the alumina cermaics:

| Properties | Unit | Alumina (AL2O3) | |||

| AL2O3≥95 | AL2O3≥99 | AL2O3≥99.5 | AL2O3≥99.8 | ||

| Volumetric density | g/cm3 | 3.7 | 3.80-3.85 | 3.85 | 3.9 |

| Hardness | HRA≥ | 86 | 88 | 88 | 88 |

| Flexural Strength | Mpa≥ | 300 | 350 | 400 | 400 |

| Maximum temperature | ℃ | 1500 | 1500 | 1500 | 1500 |

| Line expansion coefficient | ×10-6/℃ | 7.5 | 8.2 | 8.2 | 8.2 |

| Dielectric constant | εr(20℃,1MHz) | 9 | 9.2 | 9.2 | 9.2 |

| Media loss | tanδ×10-4,1MHz | 3 | 2 | 2 | 2 |

| Volumetric resistivity | Ω·cm(20℃) | 1013 | 1014 | 1014 | 1014 |

| Breakdown strength | KV/mm,DC≥ | 20 | 20 | 20 | 20 |

| Acidic resistance | mg/cm2≤ | 0.7 | 0.7 | 0.7 | 0.7 |

| Alkaline resistance | mg/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Abrasion resistance | g/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Compressive strength | Mpa≥ | 2500 | 2500 | 2500 | 2800 |

| Flexural Strength | Mpa≥ | 200 | 350 | 350 | 350 |

| Elastic modulus | Gpa | 300 | 350 | 350 | 350 |

| Poisson-Pine ratio | 0.2 | 0.22 | 0.22 | 0.22 | |

| Thermalcoefficient | W/m·K(20℃) | 20 | 25 | 25 | 25 |

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

As a manufacturer of ceramic parts, we offer customization of ceramic bars of special sizes and shapes.High Precision, Fast Delivery Time, High Composition.

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL