E-mail:admin@cerampart.com

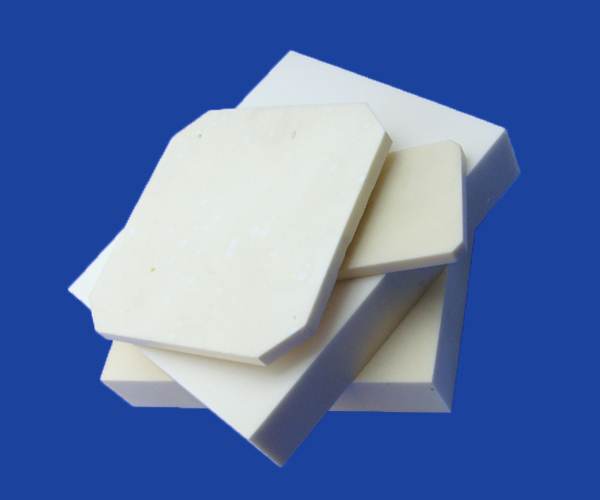

alumina ceramic tiles manufacturer high purity wear resistance advance alumina tiles

- Brand:Mingrui Ceramic

- Material:Alumina ceramic

- Precision:0.001mm

- Features:Heat resistance High purity

- Color:White Blue Ivory Black etc.

- Customized:YES OEM

Alumina Ceramic Tiles Manufacturer High Purity Wear Resistance Advance Alumina Tiles

High precision Alumina Ceramic Parts

Alumina ceramic tile is the preferred pad option for minimal particle wear areas with minimal impact, high quality alumina is manufactured to the highest standards to produce quality products that can withstand the most abrasive materials.Ceramic tile has excellent mechanical properties and excellent sliding wear resistance.

Part of available machinable specifications:

| Item | Length (mm) | Width (mm) | Height (mm) |

| 10*10 | 10 | 10 | 3--10 |

| 17.5*17.5 | 17.5 | 17.5 | 4--10 |

| 23.7*23.7 | 23.7 | 23.7 | 5--15 |

| 50*25 | 50 | 25 | 5--10 |

| 50*50 | 50 | 50 | 5--15 |

| 100*100 | 100 | 100 | 6.5--15 |

| 120*80 | 120 | 80 | 6--20 |

| 150*60 | 150 | 60 | 10--25 |

| 150*100 | 150 | 100 | 6--25 |

| 150*100 | 150 | 100 | 12--50 |

High purity alumina ceramics:

99.99% Alumina ceramic; 99.9% Alumina ceramic

Ordinary alumina ceramics:

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic.

Alumina reliability:

Better wear resistance

Higher volume resistivity

Greater mechanical strength

More chemically inert

...

Ceramic Precision Process:

|

Alumina Ceramic Parameter:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

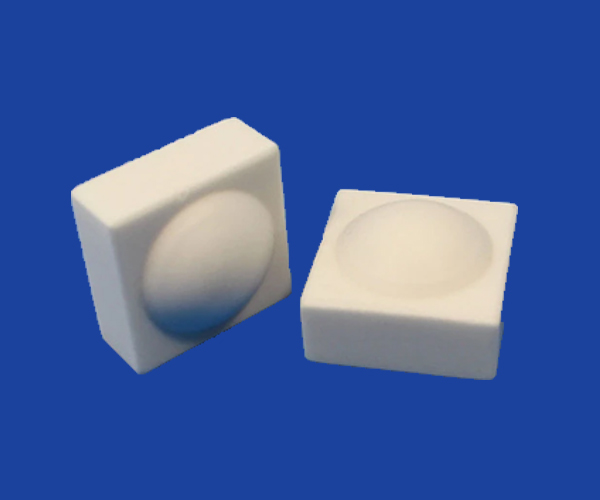

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of alumina ceramic disc or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL