E-mail:admin@cerampart.com

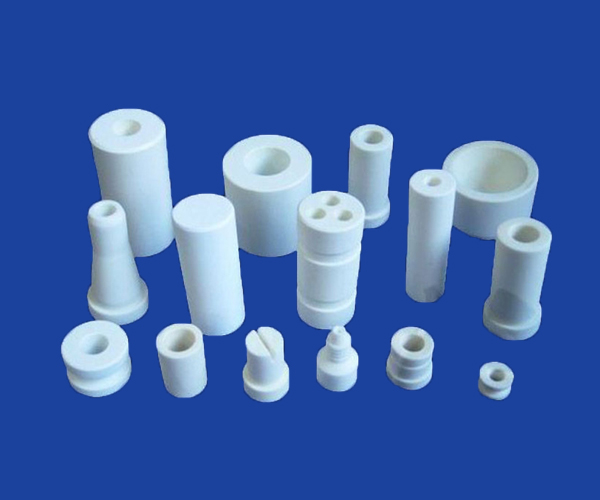

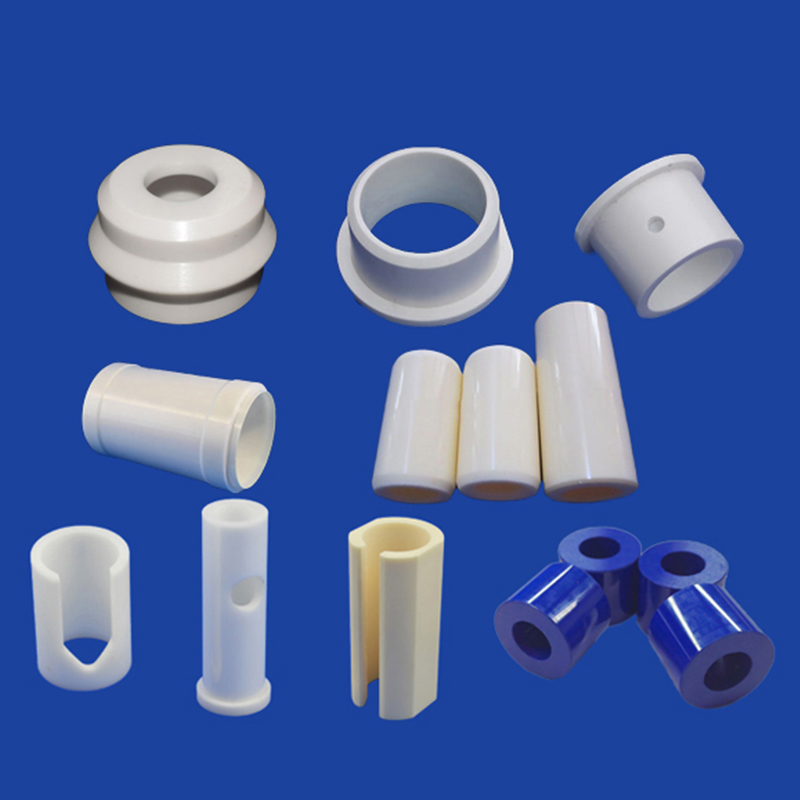

Alumina Ceramic Tubes Available 95% - 99.99% Purity Al2O3 Aluminum Oxide Ceramics Tube Multi Sizes and Shapes

- Brand:Mingrui Ceramic

- Material:Alumina ceramic

- Precision:0.001mm

- Features:Heat resistance High purity

- Color:White Blue Ivory Black etc.

- Customized:YES OEM

Alumina Ceramic Tubes Available 95% - 99.99% Purity Al2O3 Aluminum Oxide Ceramics Tube

Manufacture and Sale Multi Sizes and Shapes of Alumina Ceramic Tube

US offers a wide variety of tubes manufactured from high-performance technical ceramic materials, including 95-99.99% Alumina ceramic. Enhance performance and product life by using the material best suited to your application.

Types of alumina tubes:

Single-hole ceramic tubes, porous ceramic tubes, irregularly porous ceramic tubes,ceramic tube insulator,ceramic tube heater...

Part of us machining alumina tube case specifications:

| Tube series | Round Double Bore | Round Four Bore | Oval Double Bore | ||||

| OD | ID | OD | ID | OD | ID | OD | ID |

| .050" | .020" | .063" | .016" | .063" | .016" | .077"/.051" | .014" |

| .063" | .031" | .094" | .025" | .094" | .020" | .120"/.070" | .031" |

| .094" | .040" | .109" | .031" | .109" | .020" | .163"/.112" | .040" |

| .094" | .063" | .125" | .031" | .188" | .031" | ||

| .100" | .050" | .125" | .040" | .219" | .050" | ||

| .125" | .063" | .156" | .052" | ||||

| .156" | .094" | .188" | .040" | ||||

| .188" | .094" | .200" | .052" | ||||

High purity alumina ceramics:

99.99% Alumina ceramic; 99.9% Alumina ceramic

Ordinary alumina ceramics:

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic.

| Properties | Unit | Alumina (AL2O3) | |||

| AL2O3≥95 | AL2O3≥99 | AL2O3≥99.5 | AL2O3≥99.8 | ||

| Volumetric density | g/cm3 | 3.7 | 3.80-3.85 | 3.85 | 3.9 |

| Hardness | HRA≥ | 86 | 88 | 88 | 88 |

| Flexural Strength | Mpa≥ | 300 | 350 | 400 | 400 |

| Maximum temperature | ℃ | 1500 | 1500 | 1500 | 1500 |

| Line expansion coefficient | ×10-6/℃ | 7.5 | 8.2 | 8.2 | 8.2 |

| Dielectric constant | εr(20℃,1MHz) | 9 | 9.2 | 9.2 | 9.2 |

| Media loss | tanδ×10-4,1MHz | 3 | 2 | 2 | 2 |

| Volumetric resistivity | Ω·cm(20℃) | 1013 | 1014 | 1014 | 1014 |

| Breakdown strength | KV/mm,DC≥ | 20 | 20 | 20 | 20 |

| Acidic resistance | mg/cm2≤ | 0.7 | 0.7 | 0.7 | 0.7 |

| Alkaline resistance | mg/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Abrasion resistance | g/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Compressive strength | Mpa≥ | 2500 | 2500 | 2500 | 2800 |

| Flexural Strength | Mpa≥ | 200 | 350 | 350 | 350 |

| Elastic modulus | Gpa | 300 | 350 | 350 | 350 |

| Poisson-Pine ratio | 0.2 | 0.22 | 0.22 | 0.22 | |

| Thermalcoefficient | W/m·K(20℃) | 20 | 25 | 25 | 25 |

Alumina ceramic tube manufacturing process:

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

As a manufacturer of alumina tube, us offer customization of ceramic tubes of special sizes and shapes.High Precision, Fast Delivery Time, High Composition.

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL