E-mail:admin@cerampart.com

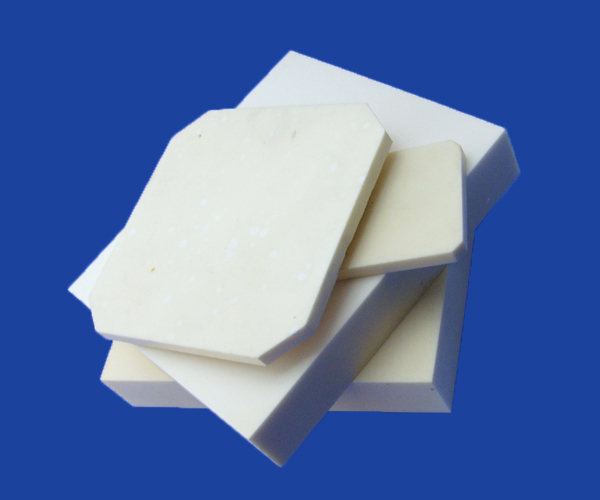

Alumina ceramic sheets with High volume resistivity wear resistance technical alumina sheets

- Brand:Mingrui Ceramic

- Material:Alumina ceramic

- Precision:0.001mm

- Features:Heat resistance High purity

- Color:White Blue Ivory Black etc.

- Customized:YES OEM

Al2O3 Alumina High Purity Ceramic Parts Manufacturer

Alumina Ceramic Sheets With High Volume Resistivity Wear Resistance Technical Alumina Sheets

Us offers a variety range of >90% alumina materials of alumina sheet are often found in our hard wearing products used within the medical, security & defence and industrial applications.

Some parts of us machinable cases specifications:

| Length (inch) | Thickness (inch) | Width (inch) |

| 0.75 | 0.165 | 0.63 |

| 0.875 | 0.187 | 0.227 |

| 0.975 | 0.2 | 0.312 |

| 1 | 0.39 | 0.25 |

| 1 | 0.177 | 0.75 |

| 1 | 0.5 | 0.75 |

| 1.17 | 0.23 | 0.355 |

| 1.875 | 0.187 | 0.875 |

| 1.875 | 0.387 | 0.875 |

| 1.875 | 0.387 | 0.875 |

| 2.95 | 0.5 | 0.95 |

| 3 | 0.125 | 2 |

| 6 | 0.25 | 4 |

| 6 | 0.5 | 4 |

High purity alumina ceramics:

99.99% Alumina ceramic; 99.9% Alumina ceramic

Ordinary alumina ceramics:

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic.

Excellent ceramics properties :

High-temperature stability; Corrosion-resistance;Lightweight, Mechanical;Low thermal expansion; Excellent thermal, High reliability;Dimensional stability;High thermal conductivity...

|

Ceramic Precision Process: Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

|

Alumina Ceramic Parameter:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of alumina ceramic sheets or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL