E-mail:admin@cerampart.com

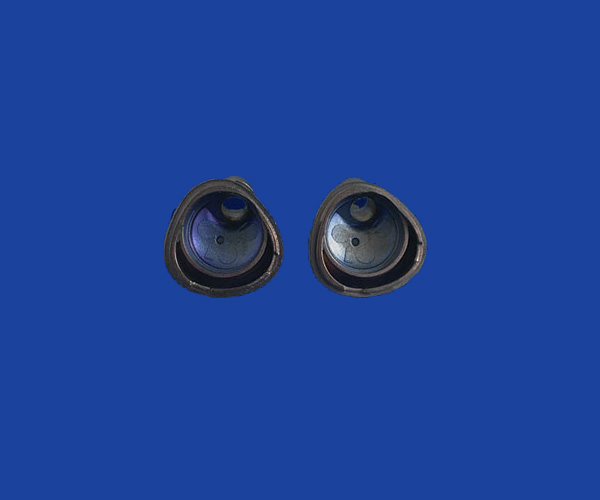

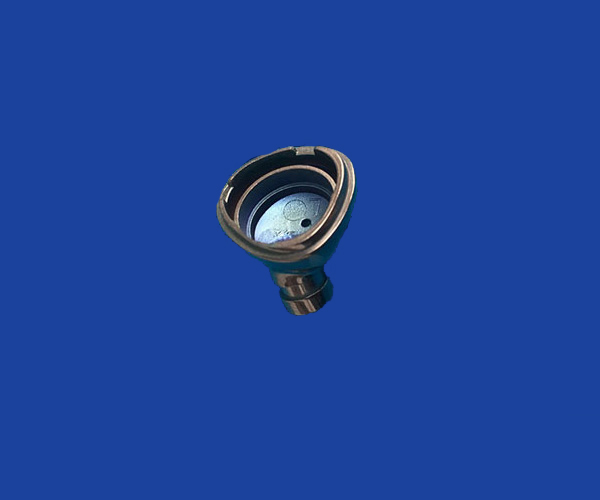

Zirconia Ceramic Earphone

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Zirconia Ceramic Earphone

Zirconia Ceramic Earphone in the material using advanced ceramic materials, its existing metal texture and glass mirror luster, and its hardness is second only to diamonds, compared to Glass can be more wear-resistant.

Compared with the traditional metal and plastic rear cover, ceramic headphones have the advantages of wear resistance, skin affinity, better air tightness and smaller electromagnetic shielding, but it also brings greater processing difficulties, compared with the metal fuselage, it is more difficult to process, so there have been few mobile phone manufacturers willing to use this material process.

The advantages of Zirconia Ceramic Earphone are as follows:

I. Technology.Ceramic ear cases generally use hd front-end unit technology, which has the advantage of making the sound quality of earphones more exquisite.

II. Second, humanization.The streamlined design of earphone earshell of ceramic earphone is delicate, and it considers the needs of listening to music for a long time humanized, so that listening to music with earphone becomes a real enjoyment.

III. Third, avant-garde fashion.The streamlined design of ceramic ear case has visual impact.In addition, ceramic material is also a huge bright spot: ceramic is the healthiest for human skin;

IV. Fourth, conform to the needs.Now it is basically a smart phone, ceramic ear shell is used in the smart phone, it is very convenient to make and receive calls and make phone calls.

Materials:

| Property | Alumina | Property | Zirconia |

| Bulk density(g/cm3) | 3.85-3.93 | The density (g/cm3) | 6.05 |

| Hardness(HRA≥) | 86 | Bibulous rate(%) | 0 |

| Bending strength(Mpa≥) | 300 | Thermal expansion coefficient(10-6 /k) | 10.5 |

| Maximum service temperature(℃) | 1500 | Young's modulus of elasticity(Gpa) | 210 |

| Linear expansion coefficient(×10-6/℃) | 7.15-7.67 | Poisson's ratio(/) | 0.3 |

| Dielectric constant(εr(20℃,1MHz)) | 9.21 | Hardness (MPa) | 1200 |

| Dielectric loss(tanδ×10-4,1MHz) | 2.5 | Bending strength (MPa) | 950 |

| Volume resistivity(Ω·cm(100℃)) | 9.2*1016 | The bending strength (MPa) | 210 |

| The compressive strength(Mpa≥) | 2500 | Compressive strength (MPa) | 2000 |

| Flexural strength(Mpa≥) | 200 | Fracture toughness(Mpa.m1/2) | 10 |

| Modulus of elasticity(Gpa) | 300 | Thermal conductivity (W/m.k) | 2 |

| Poisson's ratio | 0.2 | Specific resistivity(Ω.mm2/m) | >1015 |

| Thermal conductivity Coefficient(W/m·K(20℃)) | 20 | Maximum service temperature(℃) | 1350 |

| Dc breakdown strength | 43.7 | Acid and alkali corrosion resistance(/) | strength |

| Tensile seal strength(Mpa) | 104.4 |

|

Properties :

1. High Hardness wear resistance

2. High precision 3. Good mechanical strength 4. High temperature and chemical resistance 5. Electric insulation 6. Low thermal expansion 7. Smooth surface finish 8. Thermal Shock Resistance Material :

1. Alumina ceramic

2. Zirconia ceramic 3. Silicone carbide 4. Silicone nitride Lead-time: 20-30 days for mass production, 7-15 days for samples. |

||||||||||||||||||||||||

Dongguan Mingrui Ceramic Technology Co., Ltd.

TEL:+8618122974730

MB:+86 181 2297 4730 Tel:+86 746 3386888

Skype:+86 181 2297 4730

Email:admin@cerampart.com

ADD:No. 21, Chuangxing Road, Shangsha Second Industrial Zone, Chang'an Town, Dongguan City

HOME

HOME WHATSAPP

WHATSAPP CONTACT

CONTACT TEL

TEL